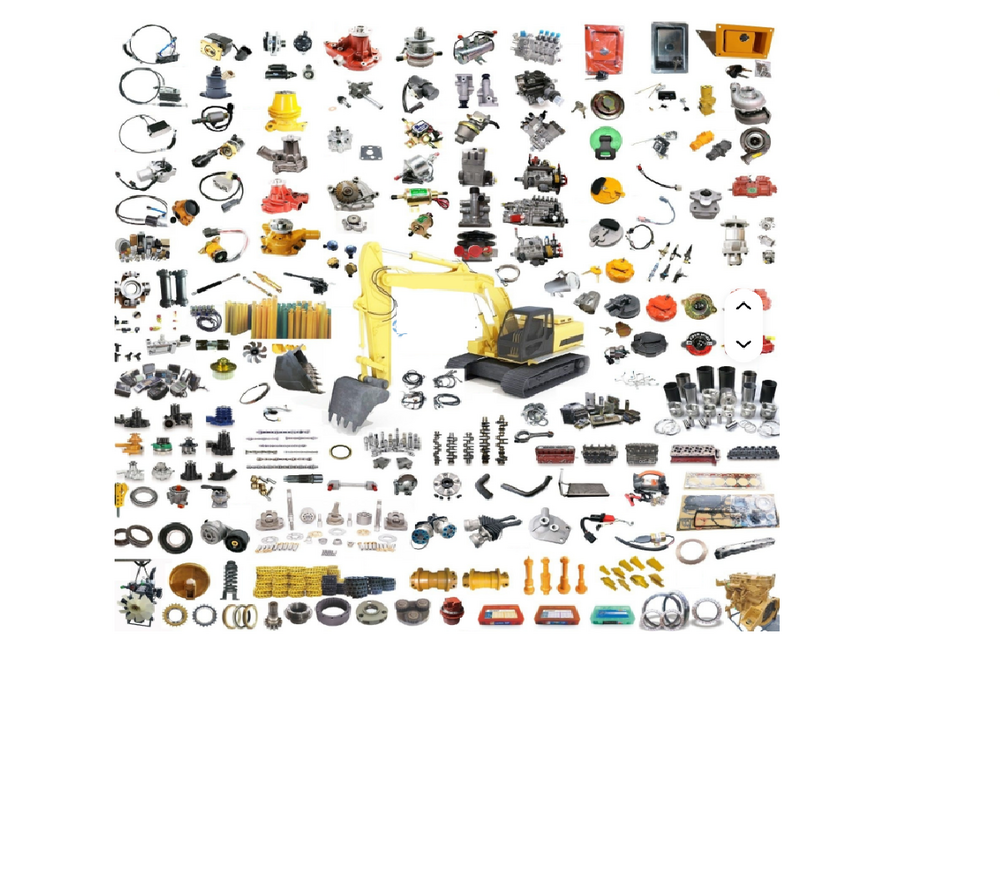

CASE GASKET CONSTRUCTION LOADER SPARE PARTS

Product Details:

- Product Type Gasket

- General Use Construction Loader Spare Parts

- Material High-grade rubber/metals

- Type Case Gasket

- Moving Type Non-moving

- Weight (kg) 0.10 kg Kilograms (kg)

- Computerized No

- Click to View more

CASE GASKET CONSTRUCTION LOADER SPARE PARTS Price And Quantity

- 7890 INR/Unit

- 1 Unit

- 1.00 - 1.00 INR/Unit

CASE GASKET CONSTRUCTION LOADER SPARE PARTS Product Specifications

- Construction Loader Spare Parts

- Non-moving

- No

- No

- Gasket

- High-grade rubber/metals

- 0.10 kg Kilograms (kg)

- Case Gasket

- Manual Installation

- Grey

- No

CASE GASKET CONSTRUCTION LOADER SPARE PARTS Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Month

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

2852154 - GASKET - CASE NEW HOLLAND CONSTRUCTION

MODEL NO . 770EX , 770EX MAGNUM , 851EX , 770NXE , 770FX ,770FX PLUS, 770ex plus ,770NX ,770NX MAGNUM , 570ST, 570SV , 770 SS

Soil compactor - 1107 DX , 1107EX , 1107FX PLUS ,1107EX PLUS

450dx mini compactor - 450 DX 450n

Tandum - 752, 752ex ,952 ex , 952 NX

BACKHOE MODELS: 580C, 580D, 580 Super E, 580K (Before Serial # JJG0020000), 584E, 585E, 586E, 480C, 480D, 480E, 480F

50mm ID x 59.25mm OD x 16.23mm Thk

Package Weight:- 0.03 kg

- 1

WE ARE SPECIALIZED IN STEERING SHAFTS, STEERING WORM, STEERING GEAR BOX ASSEMBLY, STEERING WHEELS, TRACTOR GEARS, PTO HUB, PTO DRIVE PINIONS, COUNTER SHAFT, ETC.FOR USE IN, AGRICULTURE & OTHER AFTERMARKET APPLICATION.

OUR PRODUCTS ARE MARKETED ACROSS TO WORLD OVER USA,U.K., EUROPE, LATIN AMERICA, AUSTRALIA, MIDDLE EAST, FAR EAST, AFRICAN & ASIAN CONTINENT AND OUR CUSTOMERS BASE INCLUDES OEMS LARGE REBUILDERS IN ORGANIZED SECTOR AND DISTRIBUTION HOUSES.

DEALS: MASSEY, FORD, FORDSON, FIAT, KUBOTA, DEUTZ, YANMAR, NEW HOLLAND, JOHN DEERE, CASE IH, IMT, UTB, URSUS, SAWRAJ, PERKINS, ESCORT, JCB, MAHINDRA, STEYR.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Precision Fit for CASE Loaders

Each gasket is engineered for a custom fit to match the exact contours of CASE loader engine cases. Complying with standard OEM dimensions, it guarantees a reliable seal and effortless installation, minimizing downtime and enhancing operational efficiency on-site.

Robust Material and Enduring Performance

Made from premium rubber and metals, this gasket is built to withstand extreme temperature variations from -40C up to +120C. Its chemical resistance ensures it stays effective when exposed to engine fluids like oil and coolant, safeguarding your loaders engine throughout its service life.

Easy, Direct Replacement Process

Designed for direct replacement, the gasket can be installed quickly and easily with manual toolsno automation or hydraulics required. This ensures that maintenance teams can execute gasket changes or repairs swiftly, keeping CASE loaders running smoothly with minimal interruption.

FAQs of CASE GASKET CONSTRUCTION LOADER SPARE PARTS:

Q: How do I install the CASE Gasket on my loader?

A: Installation is straightforward and can be completed manually. The gasket is a direct replacement part designed to fit CASE loader engine cases without requiring any modifications. Simply follow your loaders maintenance manual and standard safety procedures during installation.Q: What CASE loader models is this gasket compatible with?

A: The gasket is suitable for various CASE loader models. For detailed compatibility or specific OEM numbers, please contact our support team or refer to your loaders documentation.Q: When should I replace the engine case gasket on my CASE loader?

A: It is recommended to replace the engine case gasket if you notice signs of oil leakage, reduced engine performance, or during regular engine maintenance intervals to prevent leaks and maintain optimal sealing.Q: Where is this gasket manufactured and supplied from?

A: This CASE loader engine case gasket is manufactured, exported, and supplied directly from India by an experienced exporter, manufacturer, and supplier of construction loader spare parts.Q: What benefits does this compression gasket provide for my loader?

A: The gasket delivers effective engine sealing, excellent oil resistance, and leak prevention, helping to extend the service life of your loader engine and minimize maintenance costs over time.Q: What is the process for ordering and receiving the correct OEM numbered gasket?

A: You can request the specific OEM number when placing your order. Our team will assist in verifying the correct match for your CASE loader model to ensure you receive the proper gasket.Q: What materials are used in the gasket and what resistances does it offer?

A: The gasket is made from high-grade rubber and metals. It is engineered to resist oil, coolant, and a variety of chemicals, ensuring consistent performance and maintaining an effective seal even in challenging operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+