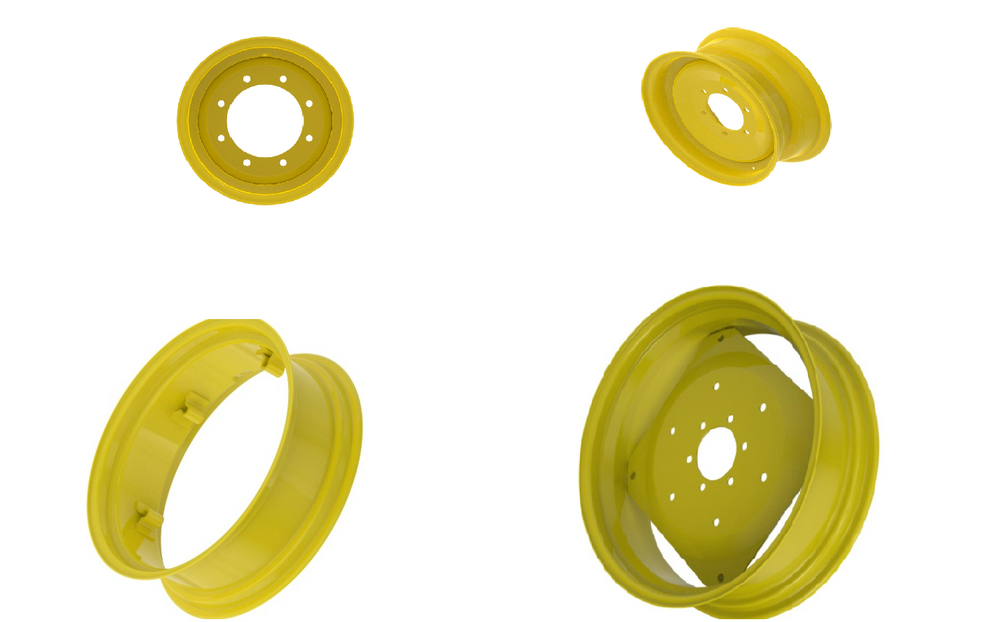

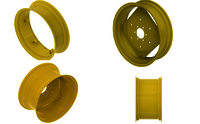

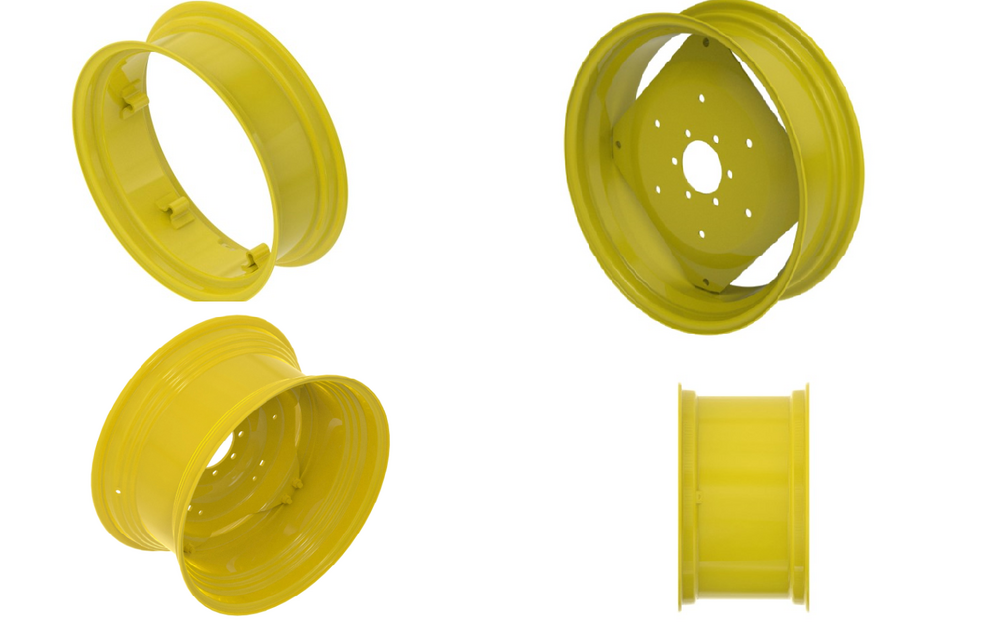

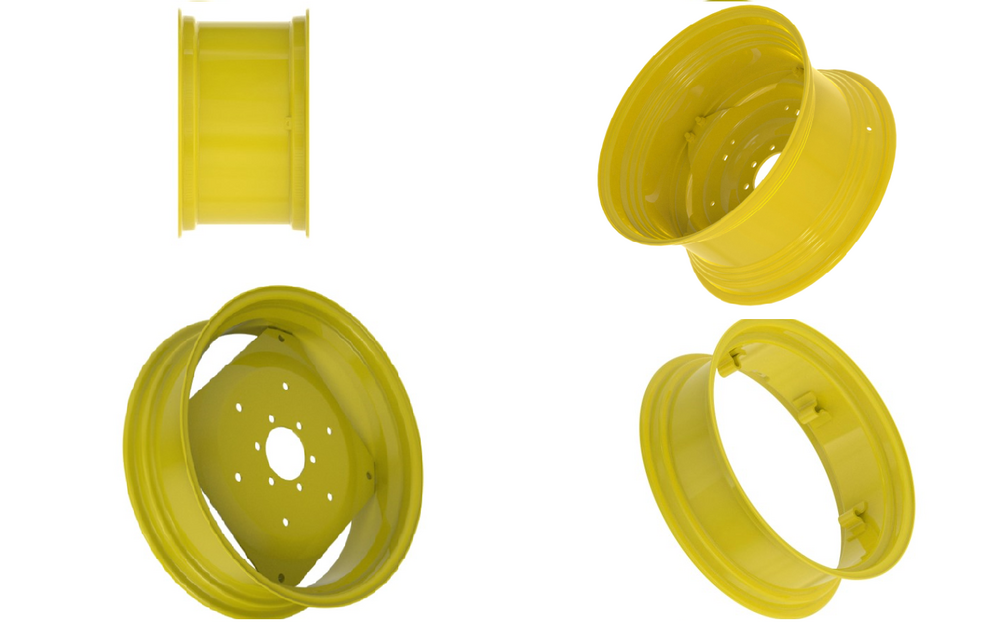

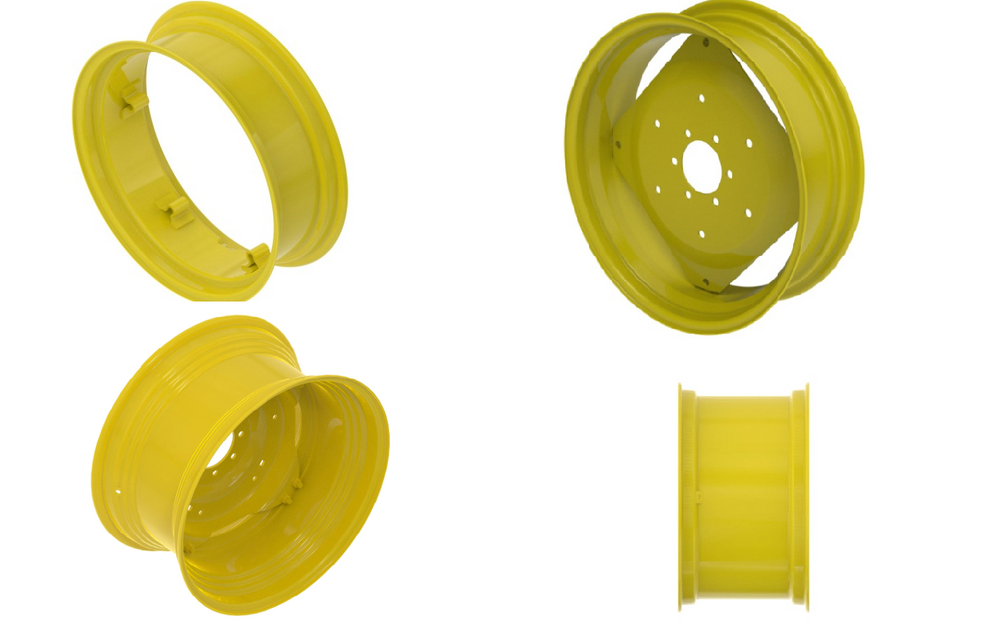

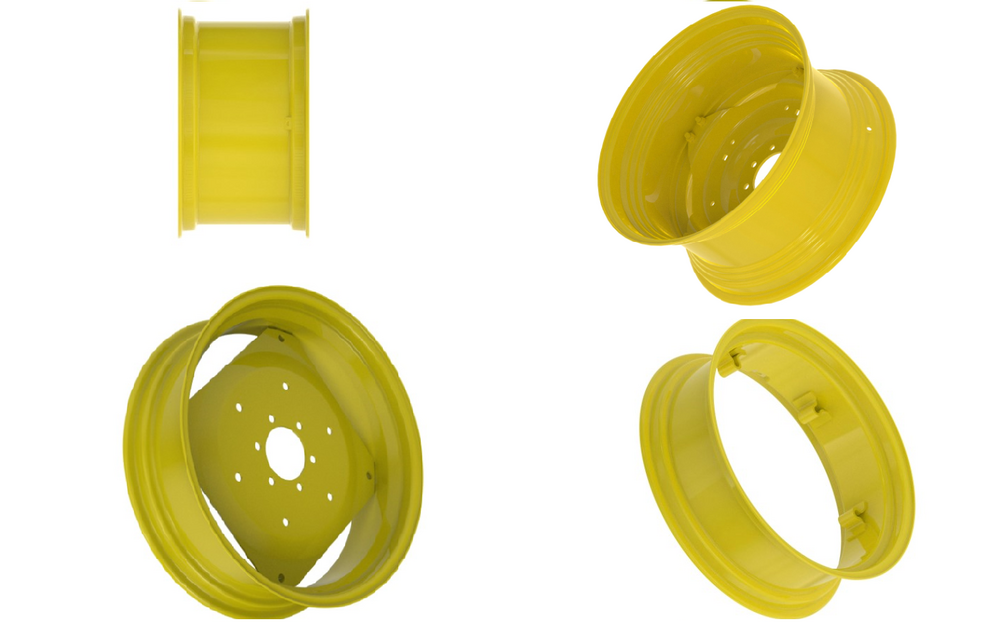

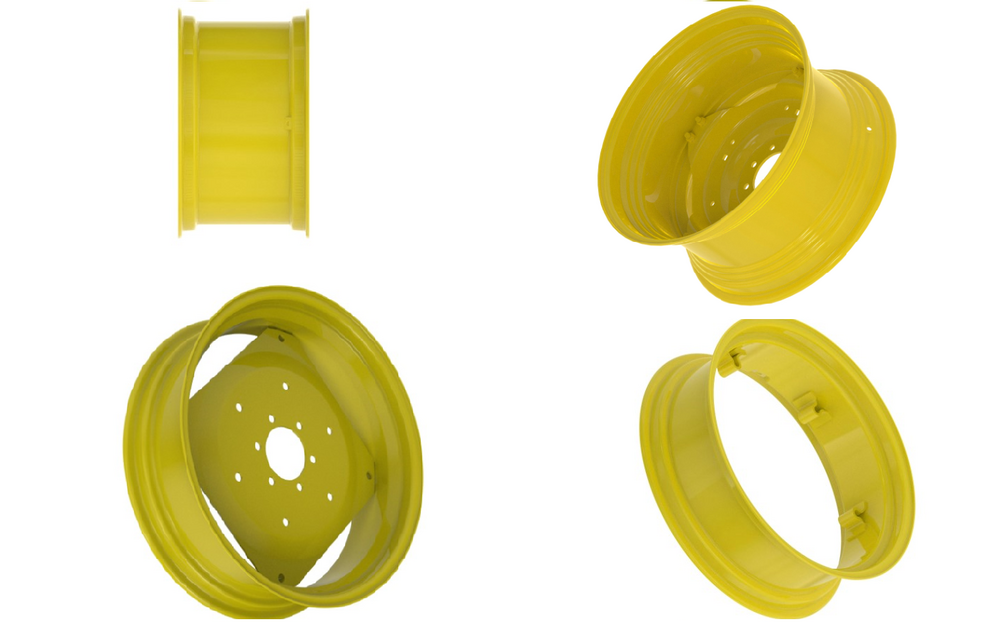

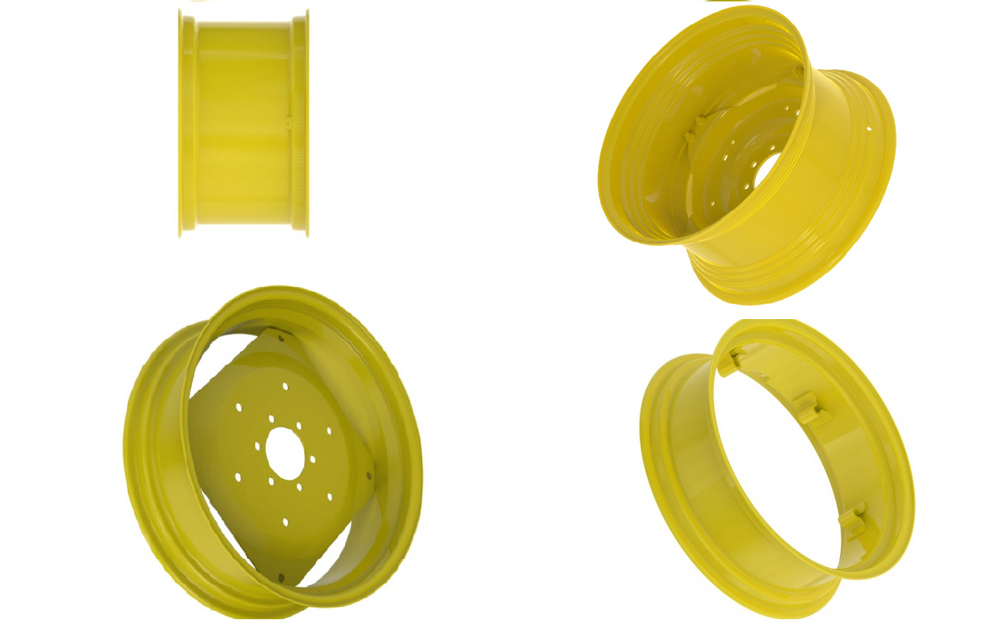

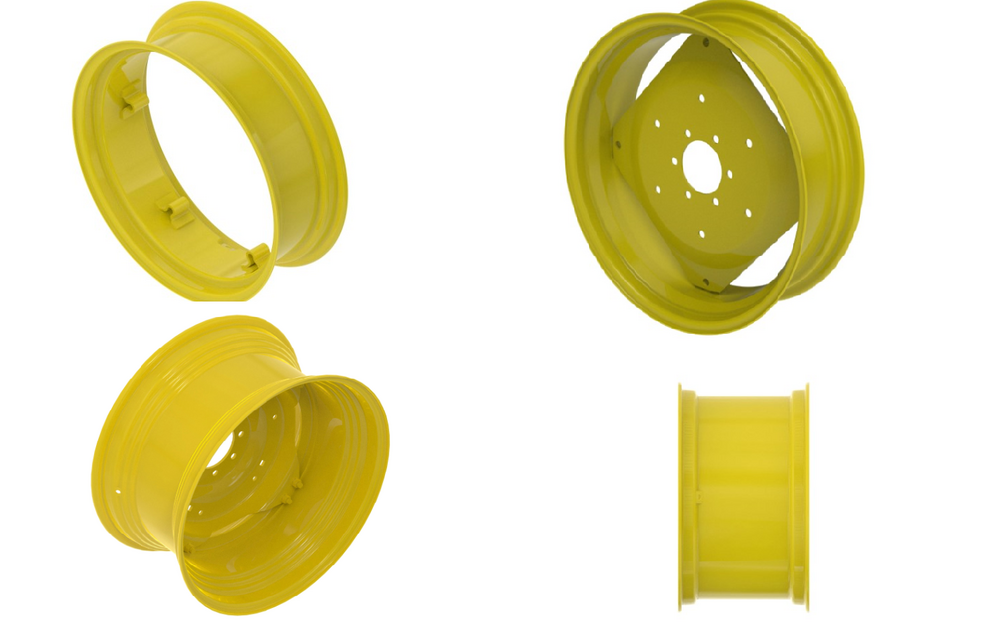

RIM AND WHEEL CENTE TRACTOR SPARE PARTS

Product Details:

- Hardness High strength, durable construction

- Sealing Type Open (non-sealed)

- Use Tractor wheel assembly and rotation support

- Pressure Range Designed to withstand heavy loads

- Mounting Type Bolt-on

- Load Capacity Up to 3000 kg Kilograms (kg)

- Part Name Rim and Wheel Center

- Click to View more

RIM AND WHEEL CENTE TRACTOR SPARE PARTS Price And Quantity

- 6578 INR/Unit

- 1 Unit

RIM AND WHEEL CENTE TRACTOR SPARE PARTS Product Specifications

- Bolt-on

- Designed to withstand heavy loads

- Forged and precisely machined

- Standard and customized sizes available

- Silver or as per requirement

- Anti-corrosion, coated

- Open (non-sealed)

- High strength, durable construction

- Smooth and uniform finish

- Rim and Wheel Center

- 8 kg to 25 kg Kilograms (kg)

- High-grade Steel

- Tractor wheel assembly and rotation support

- 0.05 mm Millimeter (mm)

- Rim and Wheel Center

- Precision CNC and forging

- Lubrication not required for rim itself, applies to wheel bearing

- Tractor Spare Parts

- Mechanical

- RWC-TRAC-01

- Up to 3000 kg Kilograms (kg)

RIM AND WHEEL CENTE TRACTOR SPARE PARTS Trade Information

- 1000 Unit Per Month

- 7 Days

Product Description

SJ20454 RIM AND WHEEL CENTE

MODEL NO . 5055E ,5075E ,5075M ,5085M ,5090M ,5095M ,5100M ,5105M ,5115,5120M

5130M

We are specialized in Steering Shafts, Steering Worm, Steering Gear Box Assembly, Steering Wheels, Tractor Gears, PTO Hub, PTO Drive Pinions, Counter Shaft, etc.for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

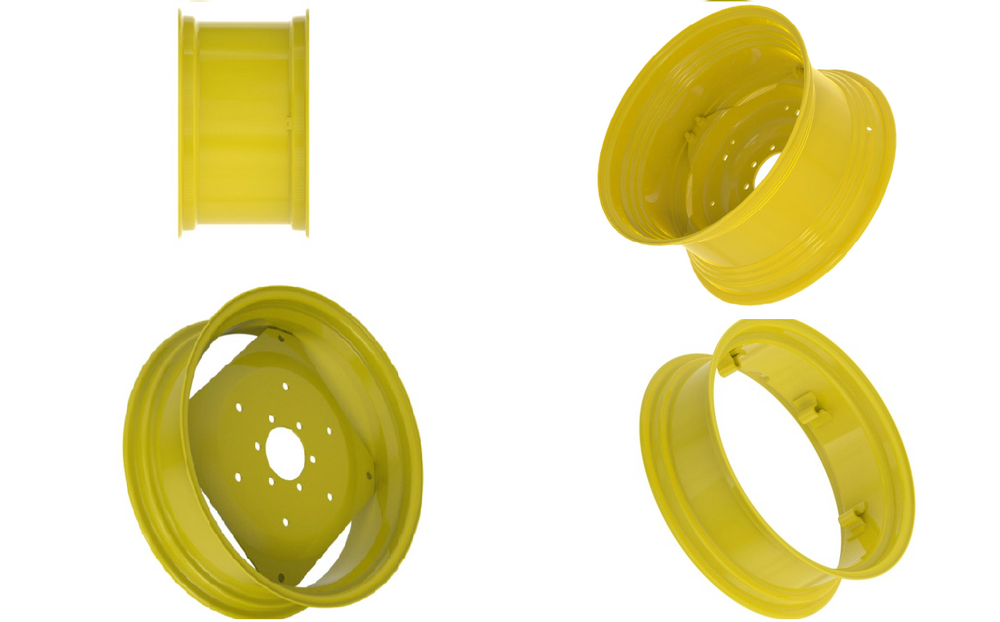

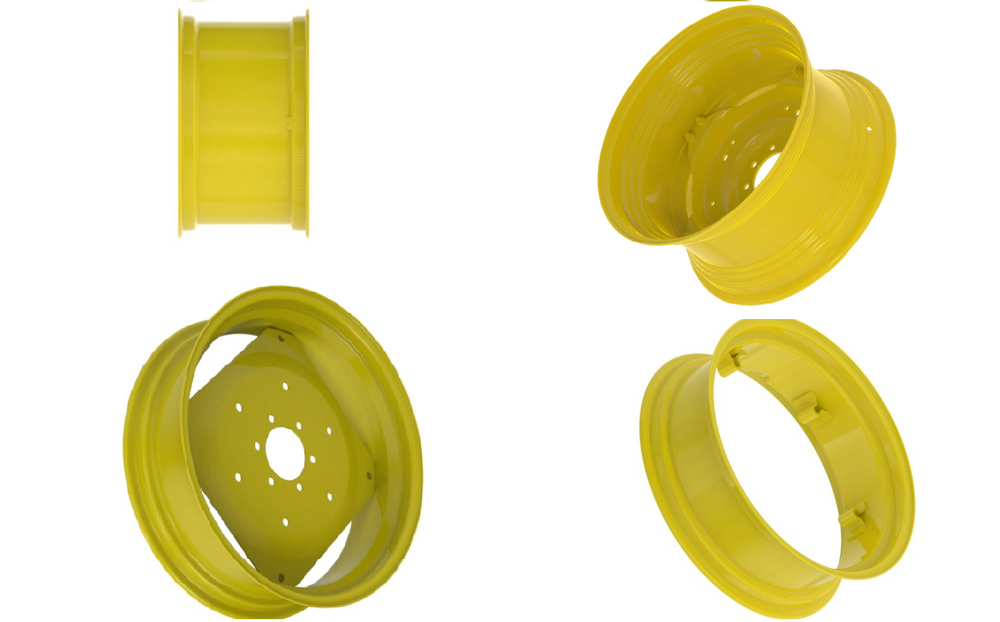

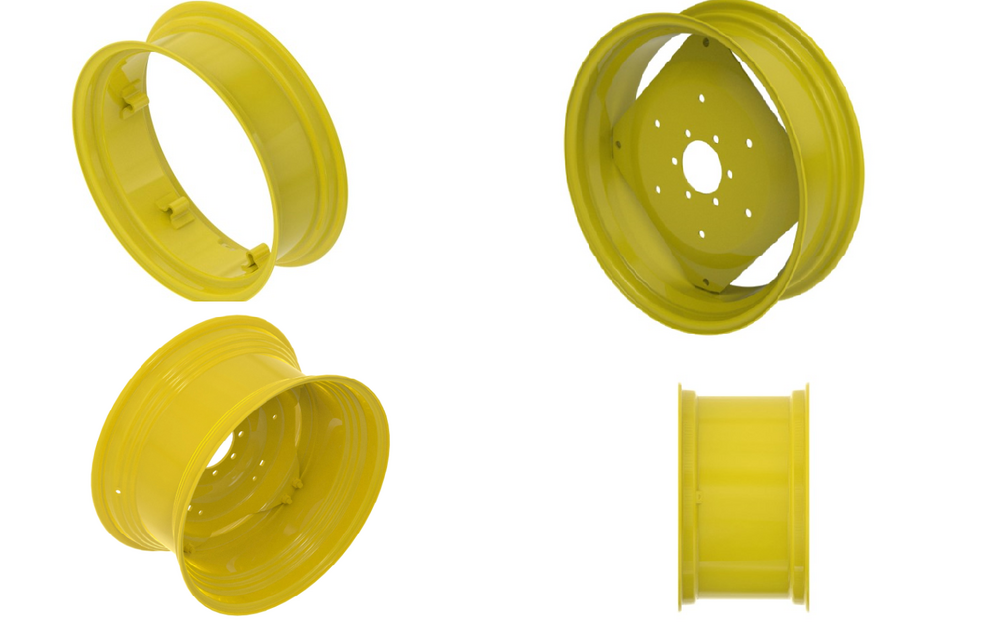

Engineered for Performance and Durability

Our rim and wheel center tractor spare parts are designed to deliver exceptional strength and resilience. They undergo advanced heat treatment and CNC forging for superior impact resistance, supporting heavy loads and extended field use. The anti-rust coating and high-grade steel construction protect against corrosion, making them ideal for prolonged agricultural operations.

Compatibility and Customization Options

These components are compatible with a wide range of tractor models and brands. Clients can choose from standard dimensions or request customized sizes and colors to match specific tractor requirements. OEM services further enhance flexibility, allowing for seamless integration across various machinery.

Safety and Ease of Maintenance

Rounded edge profiles maximize safety during handling and installation, reducing potential injury risks. Maintenance is minimalperiodic cleaning is sufficient to preserve the finish and function. The innovative design requires no lubrication on the rim, simplifying upkeep and promoting operational efficiency.

FAQs of RIM AND WHEEL CENTE TRACTOR SPARE PARTS:

Q: How can I ensure the Rim and Wheel Center fits my tractor model?

A: The Rim and Wheel Center is compatible with multiple tractor brands and models. You can provide your tractors specifications or model details so we can suggest the correct size or offer customization as needed.Q: What process is used to manufacture these tractor spare parts?

A: These parts are manufactured using precision CNC machining and forging techniques. They also undergo thermal heat treatment and are coated with an anti-corrosion layer for enhanced strength and longevity.Q: When should I consider replacing my tractors rim and wheel center?

A: Replacement is recommended if you notice deformation, excessive wear, or corrosion that compromises wheel rotation or load-bearing capacity. Regular inspection during maintenance can help identify issues early.Q: Where are these rim and wheel center parts commonly applied?

A: They are widely used in agricultural machinery and utility tractors for wheel assembly and to support efficient rotation under heavy loads, particularly in demanding farm environments.Q: What are the main benefits of using your Rim and Wheel Center spare parts?

A: Key benefits include high impact resistance, superior durability, corrosion protection, minimal maintenance needs, and customizable options to fit various tractor models, ensuring long-term, reliable performance.Q: How should I maintain the rim and wheel center for optimal performance?

A: Maintenance is straightforward: periodic external cleaning is recommended to remove dust and debris. Lubrication is not required for the rim itselffocus lubrication on the wheel bearing if needed.Q: Is OEM service available for bulk or export orders?

A: Yes, OEM services are available. Products can be tailored according to client specifications, including dimensions, color, and packaging, making them suitable for exporters, manufacturers, and suppliers worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+