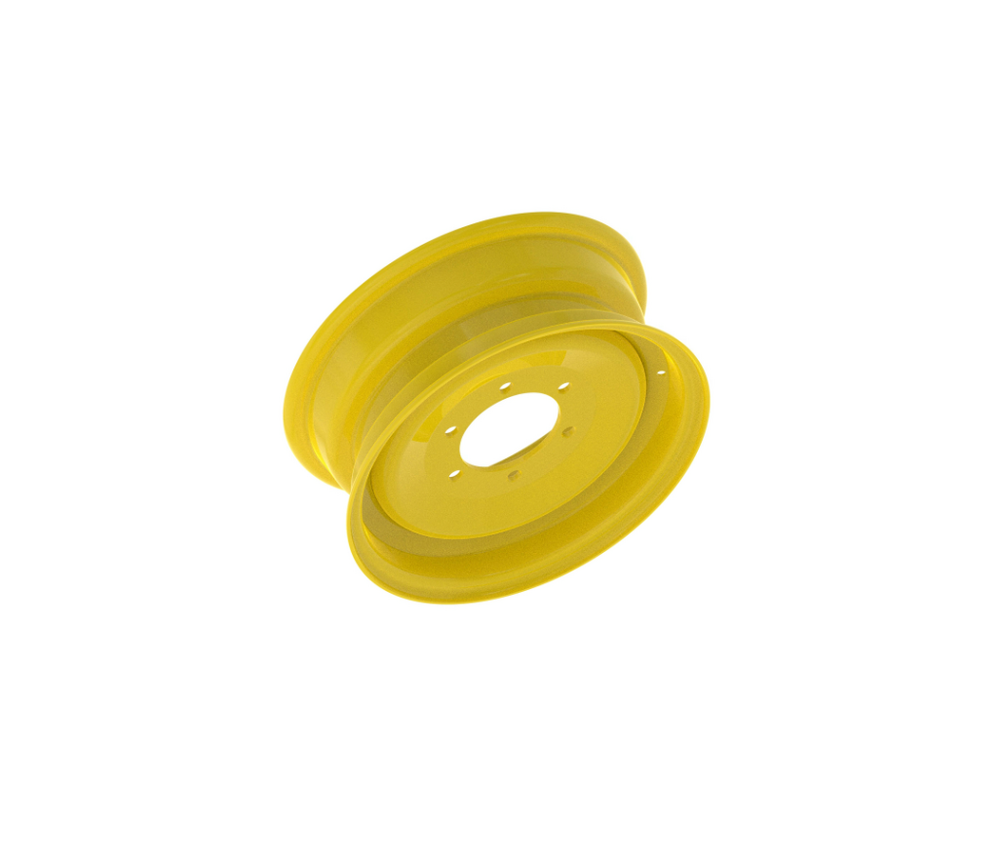

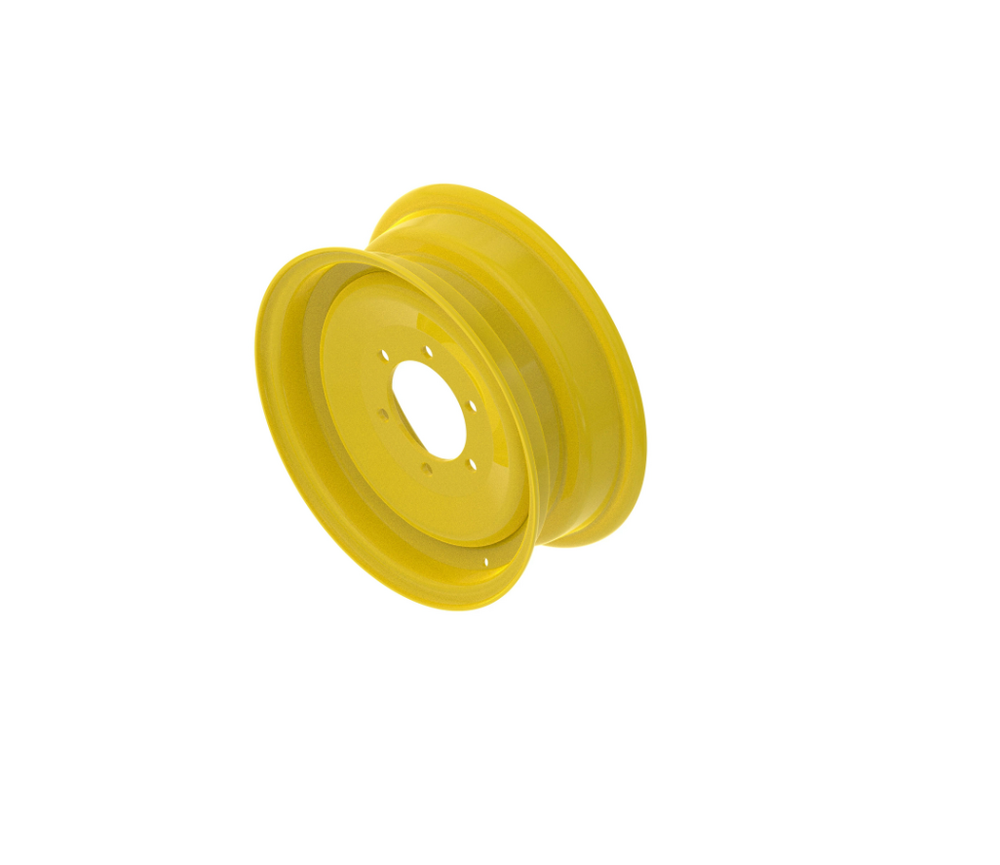

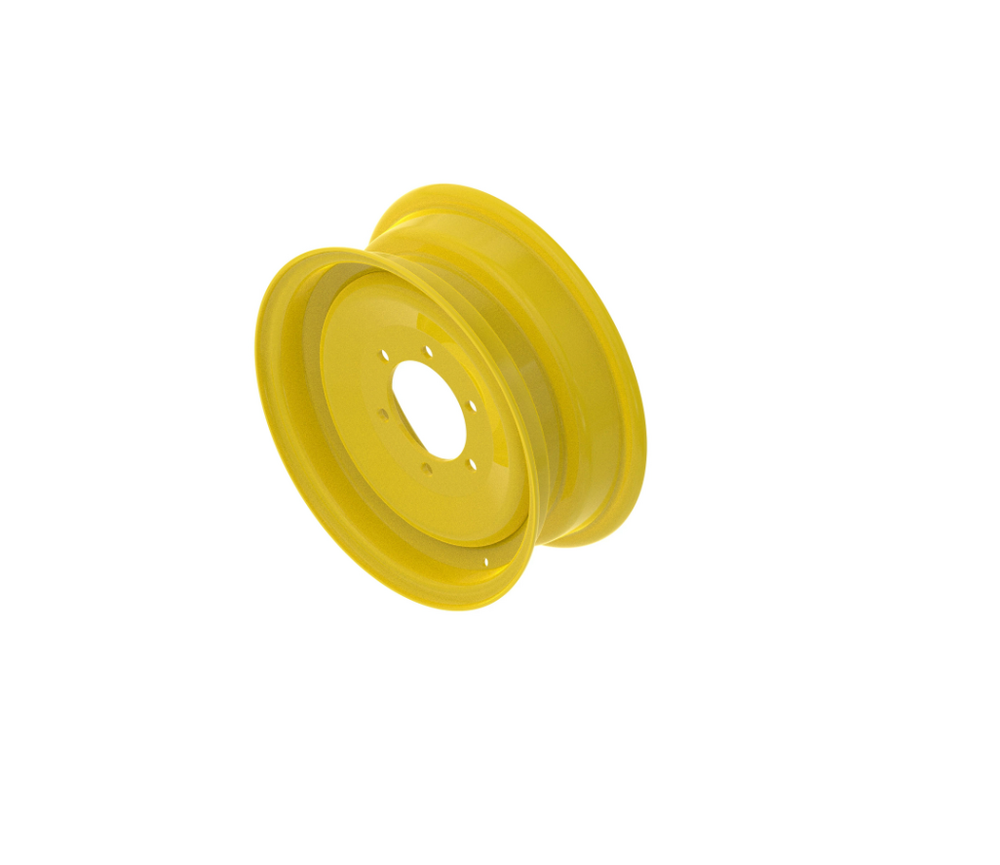

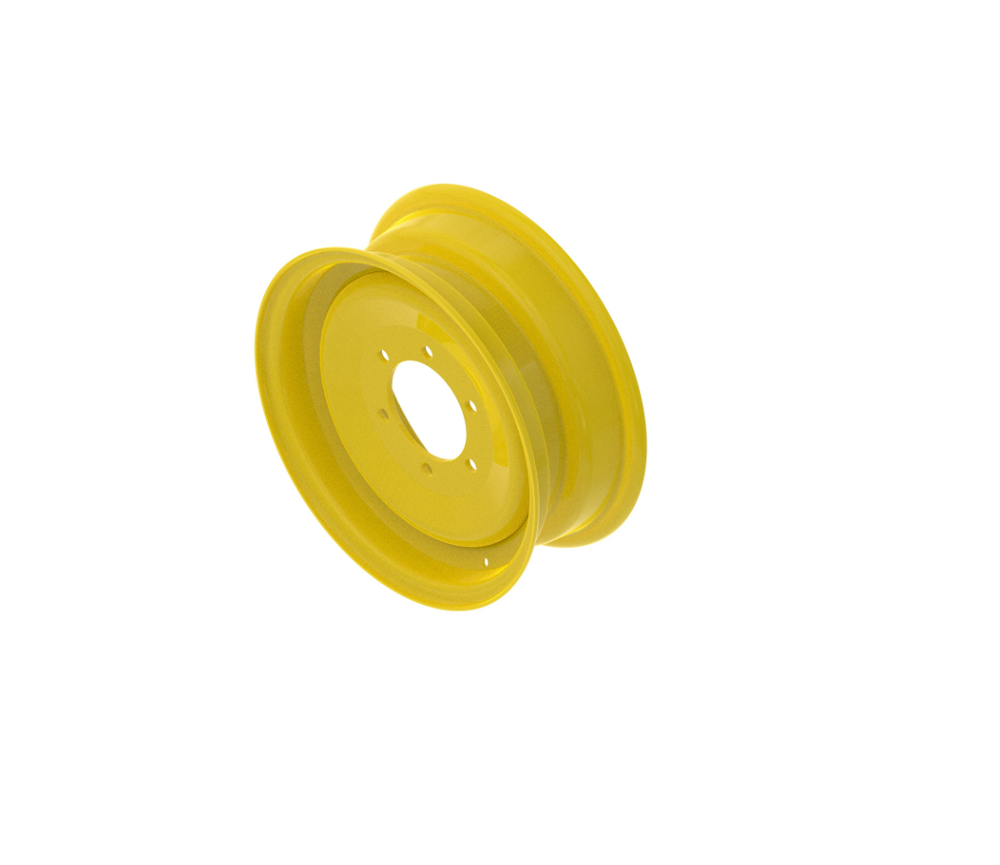

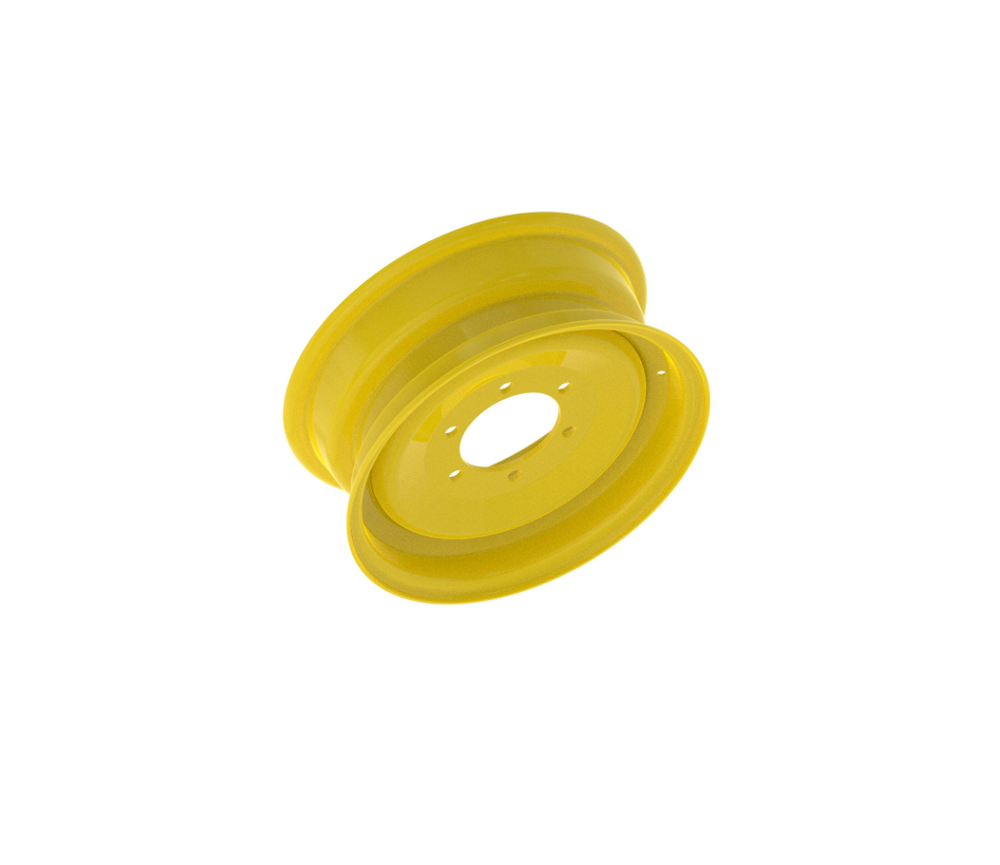

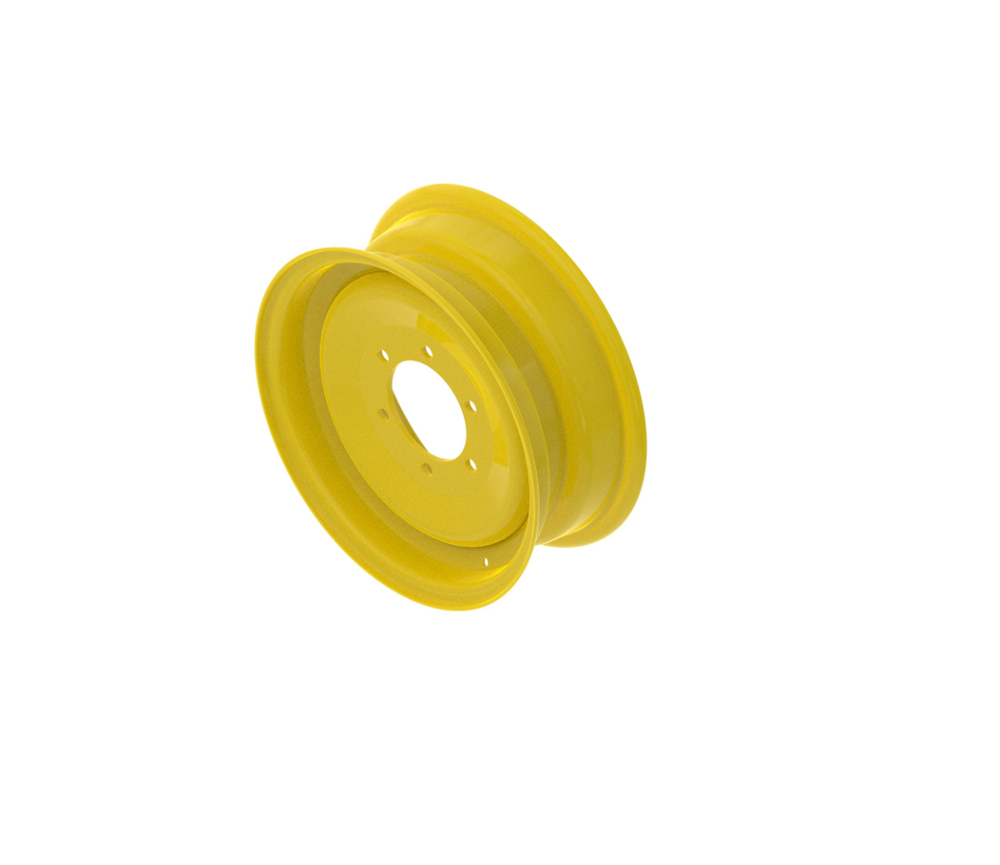

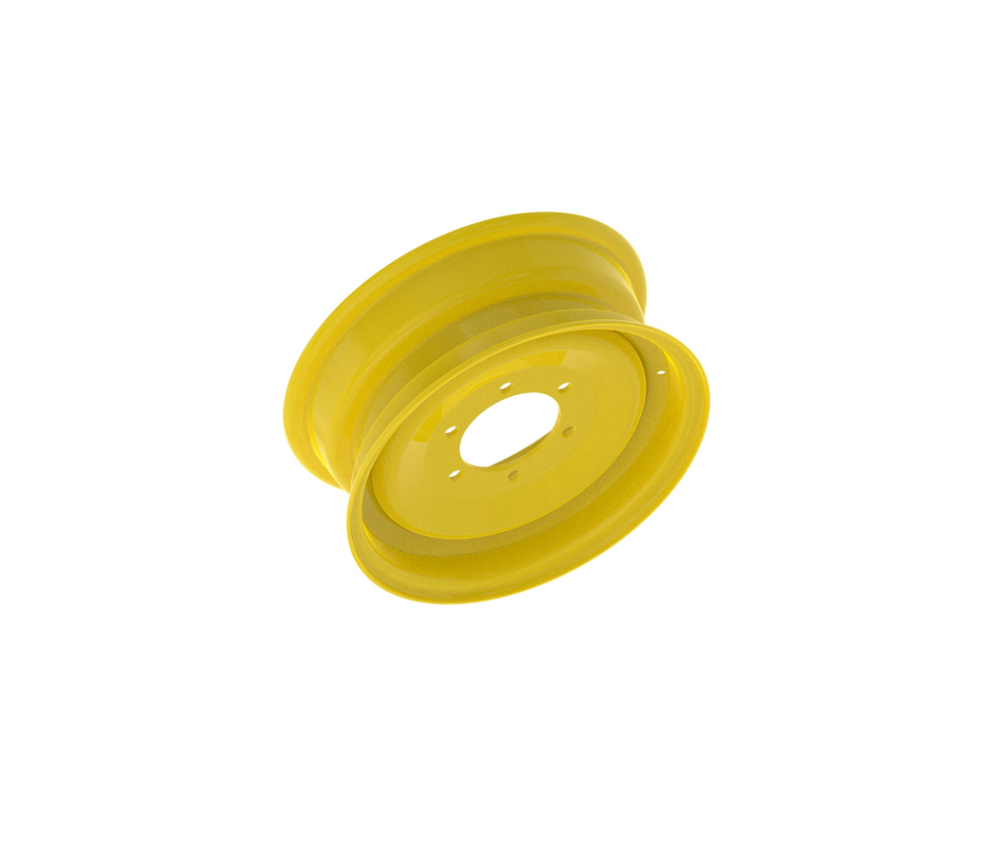

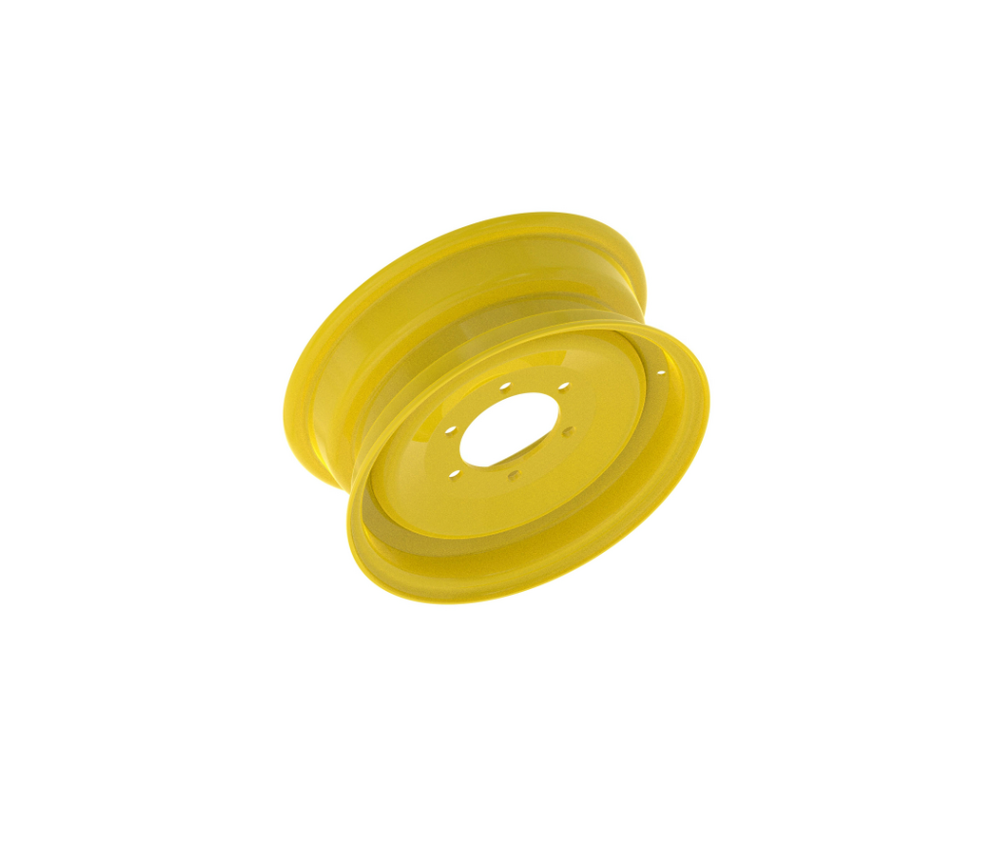

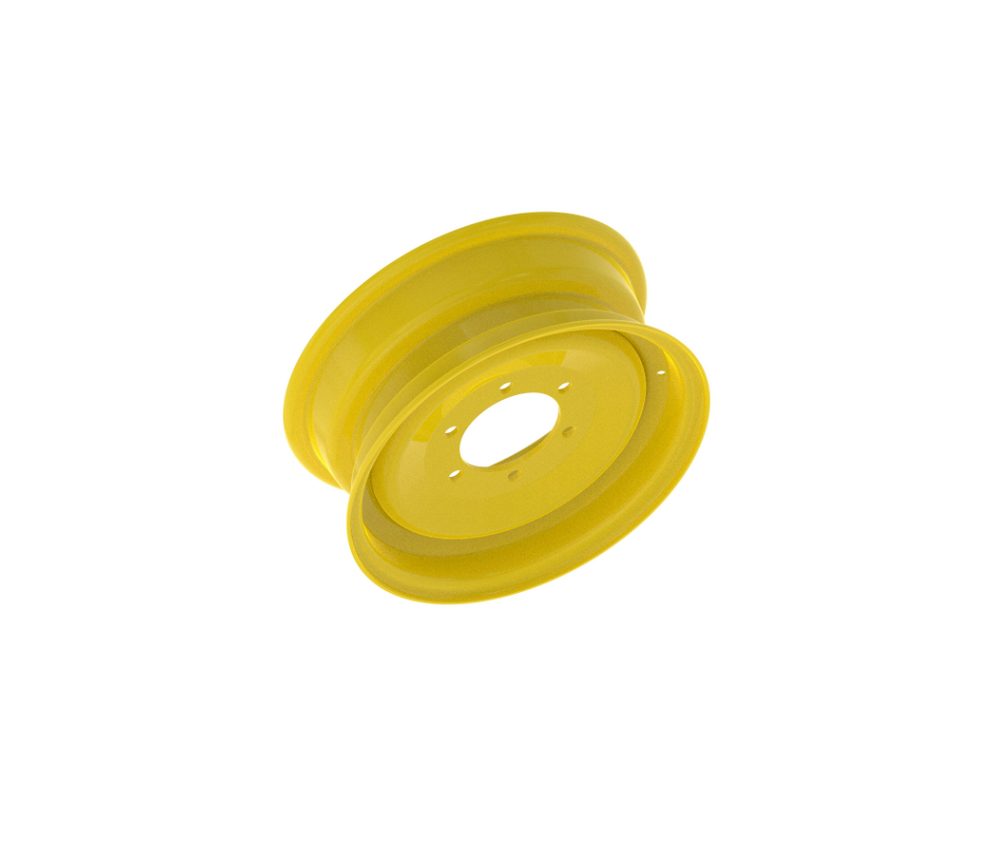

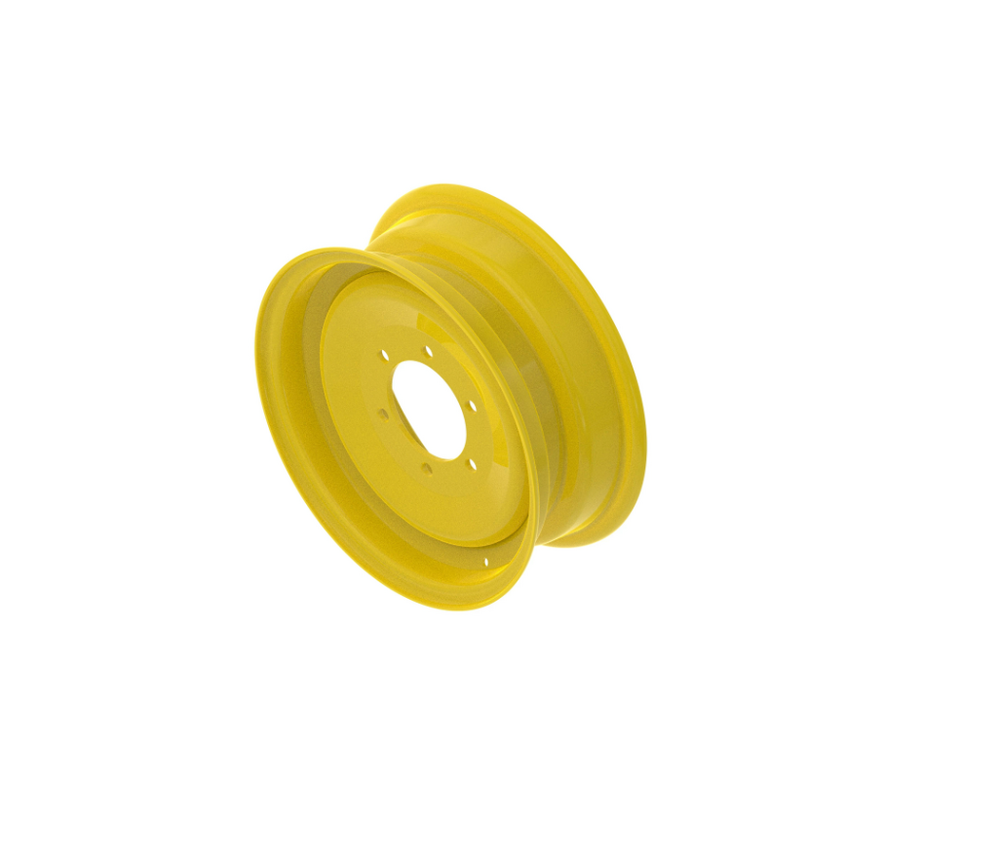

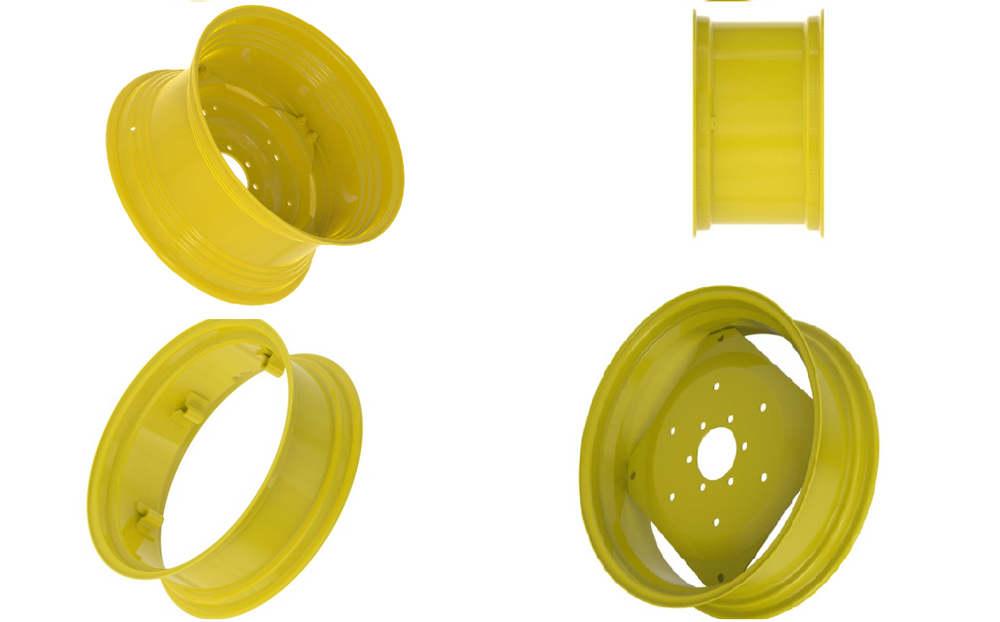

RIM AND WHEEL CENTER JOHN DEERE TRACTOR

Product Details:

- Finishing Smooth, Anti-corrosive

- Load Capacity 2200 kg Kilograms (kg)

- Pressure Range Up to 5 Bar

- Mounting Type Bolt-on/Flanged

- Use Agricultural Tractor Wheel Assembly

- Tolerance 0.05 mm Millimeter (mm)

- Part Name Rim & Wheel Center

- Click to View more

RIM AND WHEEL CENTER JOHN DEERE TRACTOR Price And Quantity

- 1 Unit

- 1.00 - 1.00 INR/Unit

- 5600 INR/Unit

RIM AND WHEEL CENTER JOHN DEERE TRACTOR Product Specifications

- Bolt-on/Flanged

- Rim & Wheel Center

- 0.05 mm Millimeter (mm)

- Yellow Powder Coated & Painted

- 457mm x 457mm x 245mm (Typical for John Deere Tractor) Millimeter (mm)

- JD-RWC-18

- OEM Standard

- Hot Rolled & Precision Machined

- HRC 30-35

- Mechanical

- 18 Inch Diameter

- Rim and Wheel Center

- Agricultural Tractor Wheel Assembly

- Tractor Wheel Component

- John Deere Yellow

- High-strength Steel

- Smooth, Anti-corrosive

- 2200 kg Kilograms (kg)

- 28 kg Kilograms (kg)

- Up to 5 Bar

RIM AND WHEEL CENTER JOHN DEERE TRACTOR Trade Information

- 1000 Unit Per Month

- 7 Days

- All India

Product Description

SJ10136: RIM AND WHEEL CENTER

MODEL NO. 5E-5210,5E-5303,5E-5310,5E,5403,544K,5045D,5045E,5050E,,5055D,5055E

,5058E,5060E,5065E,5067E,5075E,5103,5203,5203S,5204,5303,5403,5410,5503,5610

OEM NO. SJ10136

WEIGHT 44.452 KG

HEIGHT 76.835 CM

LENGTH 33.02 CM

Weare specialized in Steering Shafts, Steering Worm, Steering Gear Box Assembly, Steering Wheels, Tractor Gears, PTO Hub, PTO Drive Pinions, Counter Shaft, etc.for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Return Items identified as Eligible for Return are eligible for refund within 30 days of invoicing. Returned Items must be returned in new condition and in its original packaging with all paperwork including manuals, assembly instructions and your packing slip.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

High-Performance Construction

Manufactured from high-strength steel through a combination of hot rolling and precision CNC machining, this rim and wheel center delivers exceptional durability and performance even in challenging agricultural environments. Enhanced coatings and smooth finishing protect against corrosion and wear, while the reinforced safety lip ensures added operational safety on the field.

Precision Engineering for Reliable Operation

Designed specifically for John Deere 5000 & 6000 Series tractors, the components CNC-machined center bore and bolt pattern promote seamless installation and secure mounting. Its precise tolerance of 0.05 mm and strong flanged bolt-on design help maintain high performance at rotational speeds up to 1500 rpm and pressures up to 5 Bar. The assembly meets rigorous ISO 9001:2015 quality standards.

Long-lasting Value and Ease of Use

This rim and wheel center features a durable weather- and wear-resistant design, supporting loads up to 2200 kg and operating reliably within a temperature range of -20C to +60C. Yellow powder coating and protective packaging ensure longevity and damage-free delivery, making it a dependable partner for agricultural operations. Installation is efficient and straightforward due to its OEM-standard build.

FAQs of RIM AND WHEEL CENTER JOHN DEERE TRACTOR:

Q: How do I ensure compatibility of this rim and wheel center with my John Deere tractor?

A: This rim and wheel center is engineered specifically for John Deere 5000 & 6000 Series tractors. Confirm that your tractor model falls within these series, and check the center bore (152 mm) and bolt pattern (8 x 165 mm) to match your requirements.Q: What durability features does the product offer for agricultural environments?

A: Constructed from high-strength steel with a reinforced safety lip, this part exhibits high impact and corrosion resistance. Enhanced coatings and weather-resistant properties assure reliable performance in tough, variable field conditions.Q: When should I replace my tractors rim and wheel center?

A: You should consider replacement if you observe significant wear, cracking, or deformation, or if the wheel center no longer maintains safe mounting. Regular inspections are recommended to ensure optimum tractor performance and safety.Q: Where can I purchase and receive this tractor wheel component?

A: This product is available through authorized exporters, manufacturers, and suppliers in India. Each rim and wheel center is individually packaged in a protective carton to ensure safe and intact delivery.Q: What process is used in manufacturing this wheel center?

A: Production involves hot rolling and CNC precision machining, followed by automated welding. The component is finished with a yellow powder coating and paint, providing a smooth, anti-corrosive surface.Q: How should I use and install this rim and wheel center?

A: To install, align the component with the tractor hub using the 8-bolt, 165 mm pattern, and flange-mount it securely. Ensure the fitment meets OEM standards and that the load and rotational speeds are within recommended limits.Q: What benefits does this rim and wheel center offer over generic alternatives?

A: This OEM-standard component offers precise fitment, enhanced durability, anti-corrosive protection, and ISO 9001:2015 certified quality, contributing to dependable field performance and reduced maintenance for John Deere tractors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+