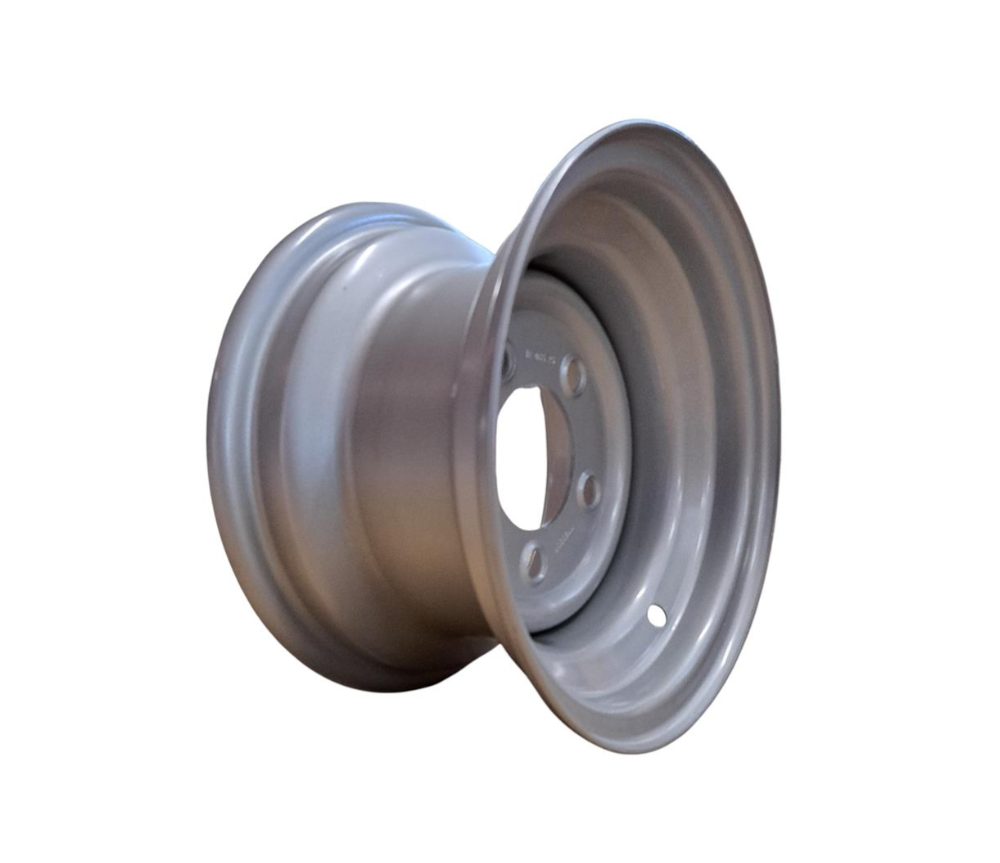

RIM AND WHEEL TRACTOR 4J x 12 , 4J x 12H , 5J x 12 , 5J x 12

Product Details:

- Model No 4Jx12 / 4Jx12H / 5Jx12

- Finishing Painted and Powder Coated

- Mounting Type Bolt-On / Center Hub Mount

- Pressure Range Recommended up to 60 PSI

- Bearing Type Not included; compatible with deep groove ball bearings

- Use Suitable for various tractors, tillers, and agri machines

- Hardness Rockwell 35-45 HRC

- Click to View more

RIM AND WHEEL TRACTOR 4J x 12 , 4J x 12H , 5J x 12 , 5J x 12 Price And Quantity

- 1 Unit

- 5678 INR/Unit

RIM AND WHEEL TRACTOR 4J x 12 , 4J x 12H , 5J x 12 , 5J x 12 Product Specifications

- 0.1 mm

- Depends on Model (Typical Diameter 12 inch, Width 4-5 inch)

- Wheel Rim

- Recommended up to 60 PSI

- Up to 500 kg (depending on model)

- Precision Formed, Welded Construction

- Standard Black/Silver/Custom Options

- Heavy-duty Steel

- Bolt-On / Center Hub Mount

- Mechanical/Friction Driven

- Painted and Powder Coated

- Tractor Rim and Wheel

- Rim and Wheel Assembly

- Anti-corrosive Powder Coating

- 4Jx12 / 4Jx12H / 5Jx12

- Approx. 7-10 kg each (model dependent)

- Rockwell 35-45 HRC

- Cold Rolled/Formed

- Suitable for various tractors, tillers, and agri machines

- Not included; compatible with deep groove ball bearings

- 4J x 12, 4J x 12H, 5J x 12

RIM AND WHEEL TRACTOR 4J x 12 , 4J x 12H , 5J x 12 , 5J x 12 Trade Information

- All India

Product Description

4J x 12 / 4J x 12H / 5J x 12 / 5J x 12 RIM AND WHEEL TRACTOR

We are specialized in Tractor Steering Shafts, Steering Worm, Tractor Steering Gear Box Assembly, Tractor Steering Wheels, Tractor Gears, Tractor PTO Hub, Tractor PTO Drive Pinions, Tractor Counter Shaft, etc. for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Rugged Construction and Superior Finish

Each wheel rim in this range is cold rolled and spot welded for enhanced reliability under rigorous agricultural use. Painted and powder-coated for corrosion resistance as per ISO standards, these rims offer a long service life even in harsh field conditions. The robust design caters to both OEM and ODM needs, supporting universal fit and easy mounting.

Precision Engineering for Agricultural Demands

With a Rockwell hardness of 35-45 HRC and a tolerance of 0.1 mm, these rims maintain structural integrity under high loads and extended usage. The options for solid dish or multi-spoke configuration enhance strength while accommodating standard bearings and pressures up to 60 PSI, meeting the varied needs of tractors and farming implements.

FAQs of RIM AND WHEEL TRACTOR 4J x 12 , 4J x 12H , 5J x 12 , 5J x 12:

Q: How can I determine the correct rim and wheel model (4J x 12, 4J x 12H, or 5J x 12) for my agricultural tractor or implement?

A: To select the best fit, check your tractors required wheel width and diameter, along with the bolt pattern and PCD specifications. The model numbers indicate rim width and hole configuration, while dimensions and bolt patterns (4/5/6 holes, PCD 100 mm or 115 mm) should match your machines hub and mounting requirements.Q: What are the benefits of using these powder-coated, spot-welded rims for agricultural applications?

A: These rims offer exceptional durability thanks to their heavy-duty steel construction, anti-corrosive powder coating, and spot-welded joints. This ensures they withstand harsh outdoor environments, resist rust and corrosion, and provide reliable service with minimal maintenance in agricultural operations.Q: Where can these tractor rims be mounted, and what mounting types are supported?

A: The rims are designed for universal fit on a wide range of compact tractors, power tillers, and related implements. They support both bolt-on and center hub mounting to suit existing machinery configurations, making them versatile and easy to install.Q: What is the process for ordering customized OEM or ODM wheel rims?

A: The manufacturer offers OEM and ODM support. You can request custom dimensions, colors, or hub specifications during the inquiry process. Provide your machines details, and the factory will engineer rims to your specific requirements, ensuring optimal compatibility.Q: When should I replace my existing tractor wheel rims with these new models?

A: Replace your old rims if you notice signs of rust, fatigue, deformation, or persistent air loss. Upgrading to these reinforced, powder-coated wheels boosts reliability and safety, especially if you operate in demanding or corrosive field conditions.Q: What is the typical usage and load capacity for these tractor rims?

A: These wheels are suitable for regular agricultural operations such as plowing, tilling, and hauling. Depending on the model, they support loads up to 500 kg each, ensuring strong, safe performance for various tractor-powered implements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+