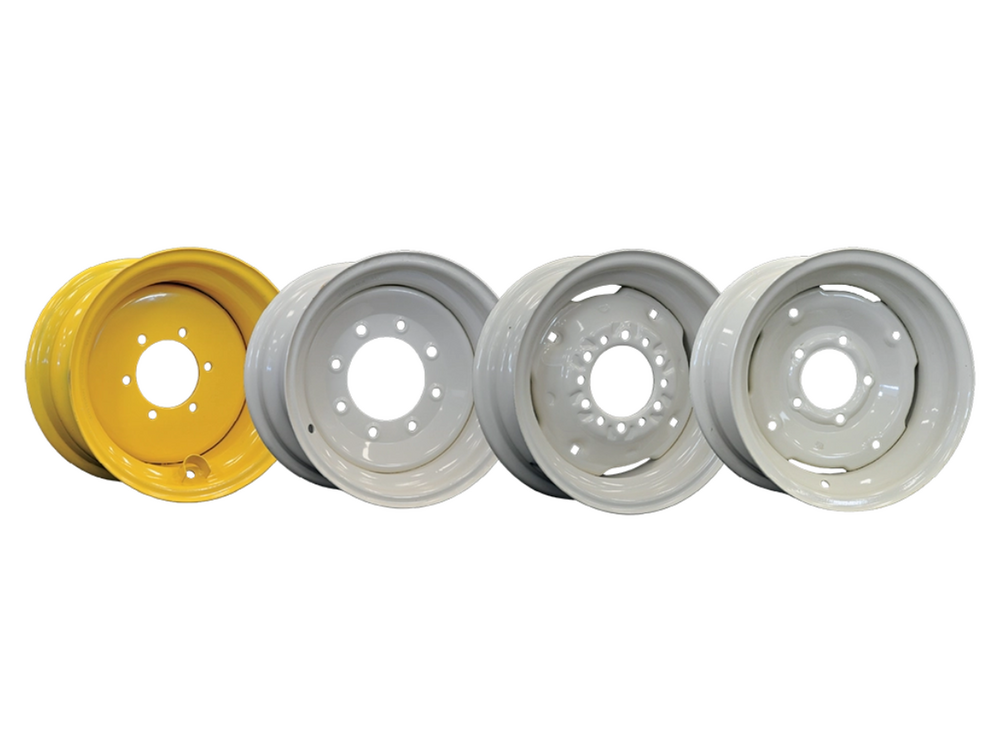

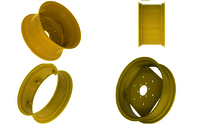

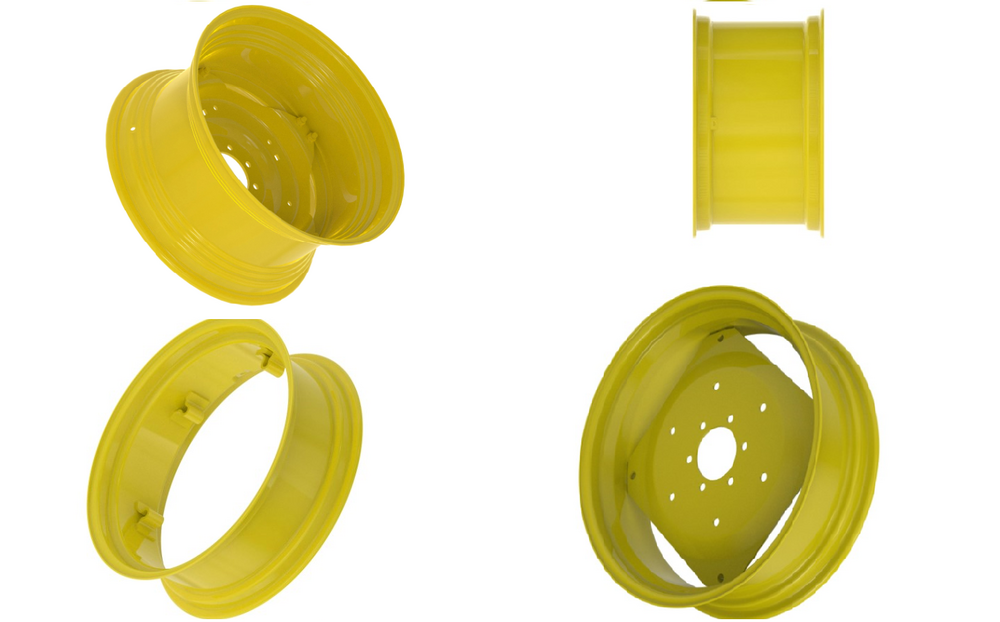

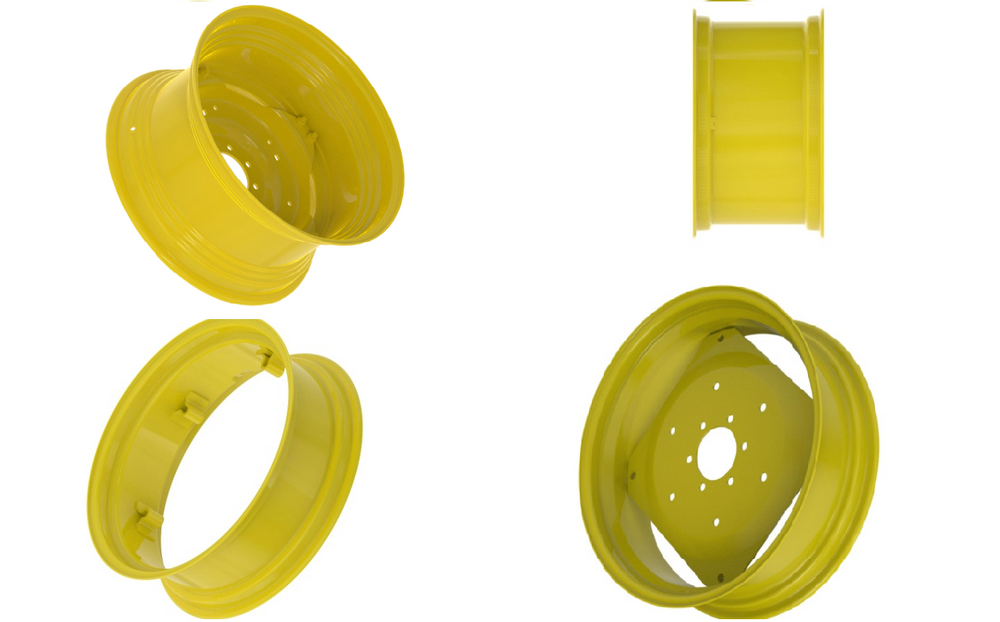

WHEEL AND RIM 500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2

Product Details:

- Pressure Range Up to 7.5 Bar (Depending on tire specification)

- Part Name 500/60-22.5 AG Wheel Rim

- Tolerance 0.5 mm Millimeter (mm)

- Use For agriculture trailers, implements, and machinery

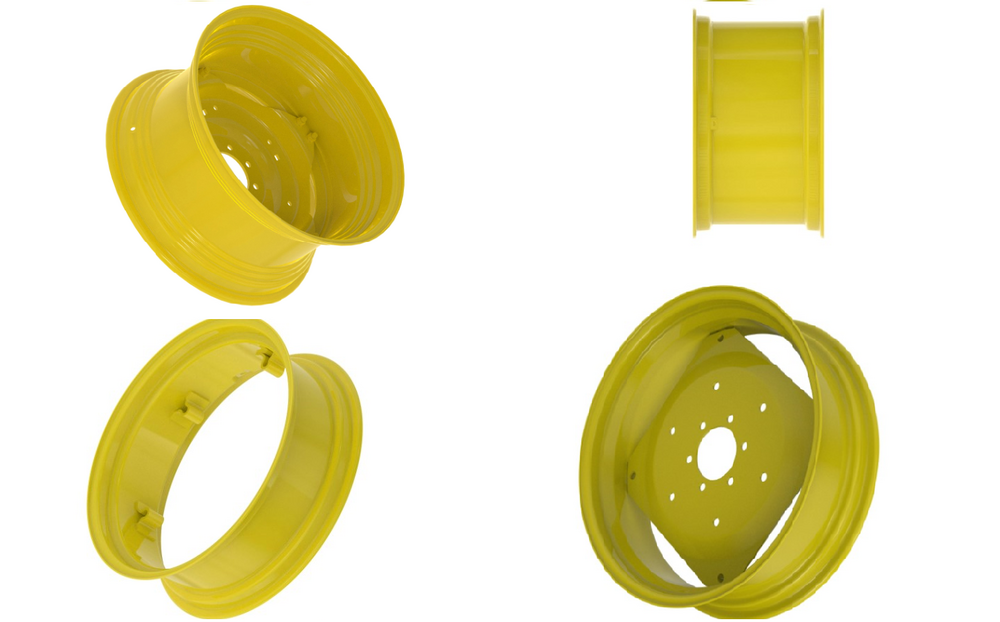

- Mounting Type Bolt-on Fitment

- Sealing Type Air-sealing Bead Seat

- Model No AG 16 x 22.5 H2 / AG 20 x 22.5 H2

- Click to View more

WHEEL AND RIM 500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2 Price And Quantity

- 7899 INR/Unit

- 1 Unit

- 1.00 - 1.00 INR/Unit

WHEEL AND RIM 500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2 Product Specifications

- Wheel and Rim Assembly

- Approx. 70-95 kg (Depends on Rim Size) Kilograms (kg)

- 500/60-22.5

- Agricultural Wheel and Rim

- Up to 7.5 Bar (Depending on tire specification)

- 500/60-22.5 AG Wheel Rim

- Up to 7000 kg (Depending on application) Kilograms (kg)

- 235-270 HB

- Phosphated and Powder Coated

- 0.5 mm Millimeter (mm)

- AG 16 x 22.5 H2 / AG 20 x 22.5 H2

- Standard Painted Finish (Grey/Black)

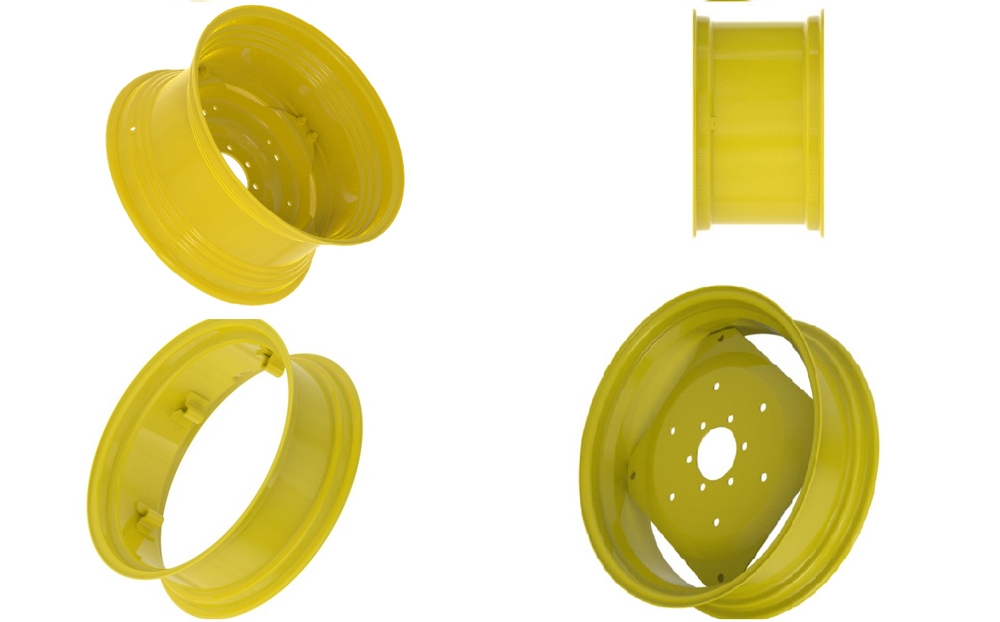

- Air-sealing Bead Seat

- Manual/Tractor Driven

- High Strength Steel

- Advanced Robotic Welding

- Bolt-on Fitment

- Anti-corrosive Powder Coating

- Cold Rolled & Welded

- 500 mm x 16/20 x 22.5 inch Inch (in)

- For agriculture trailers, implements, and machinery

WHEEL AND RIM 500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2 Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Month

- 7 Days

- Asia, Australia, North America, Eastern Europe

- All India

Product Description

500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2

we are Specialized in Tractor Steering Shafts, Steering Worm, Tractor Steering Gear Box Assembly, Tractor Steering Wheels, Tractor Gears, Tractor PTO Hub, Tractor PTO Drive Pinions, Tractor Counter Shaft, etc. for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Engineered Durability for Agricultural Demands

These wheel rims are crafted from fully heat-treated high-strength steel and utilize a multi-layer powder-coat finish, maximizing resistance against corrosion and mechanical weareven in challenging environments. The advanced robotic welding technique guarantees consistent structural integrity, supporting intensive agricultural operations for years.

Flexible Customization to Suit Your Machine

Offset, PCD, and bolt pattern can be tailored, ensuring the rim precisely matches the machinery requirements. With a standard 10-bolt design, customizable expectations, and a 0.5 mm tolerance, these rims deliver versatile compatibility for tractors, implements, and trailers across agricultural applications.

FAQs of WHEEL AND RIM 500/60-22.5 AG 16 x 22.5 H2 AG 16 x 22.5 H2 AG 20 x 22.5 H2:

Q: How do I determine if the 500/60-22.5 AG wheel rim fits my agricultural equipment?

A: To ensure proper fit, verify your machinerys tire size (500/60-22.5), bolt pattern (10 holes), PCD (281 mm or customized), center bore (221 mm), and offset requirements. The rims features can be tailored for specialized machinery. Consult your equipment manual or contact the supplier for compatibility.Q: What benefits does the multi-layer corrosion-resistant paint process provide?

A: The multi-layer corrosion-resistant process, including phosphating and powder coating, shields the rim from rust, chemical exposure, and environmental wear. This extends the rims service life, reduces maintenance costs, and maintains visual appeal even under intensive field conditions.Q: When should the rim offset be customized?

A: Offset customization is recommended when your equipments axle or hub specifications differ from standard configurations, or if you require specific tracking, load distribution, or clearance. Share your machinerys technical details with the manufacturer to achieve an ideal fit and performance.Q: Where can these rims be used beyond agricultural tractors?

A: These rims are suitable not only for agricultural tractors, but also for implements, trailers, and other related machinery where the specified dimensions, load ratings, and bolt properties meet the application requirements.Q: What is the manufacturing process for these wheel rims?

A: The process includes cold rolling high-strength steel, robotic precision welding, thorough heat treatment for hardness, phosphating, and multi-layer powder coating for a corrosion-resistant finish. Each rim is quality-inspected to conform with ISO/TS16949 standards.Q: How do I benefit from the fully heat-treated, high-strength steel construction?

A: Full heat treatment increases the rims structural strength, resistance to deformation under load, and overall durability. This ensures reliable performance during heavy-duty agricultural work and enhances the lifespan of the rim assembly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+