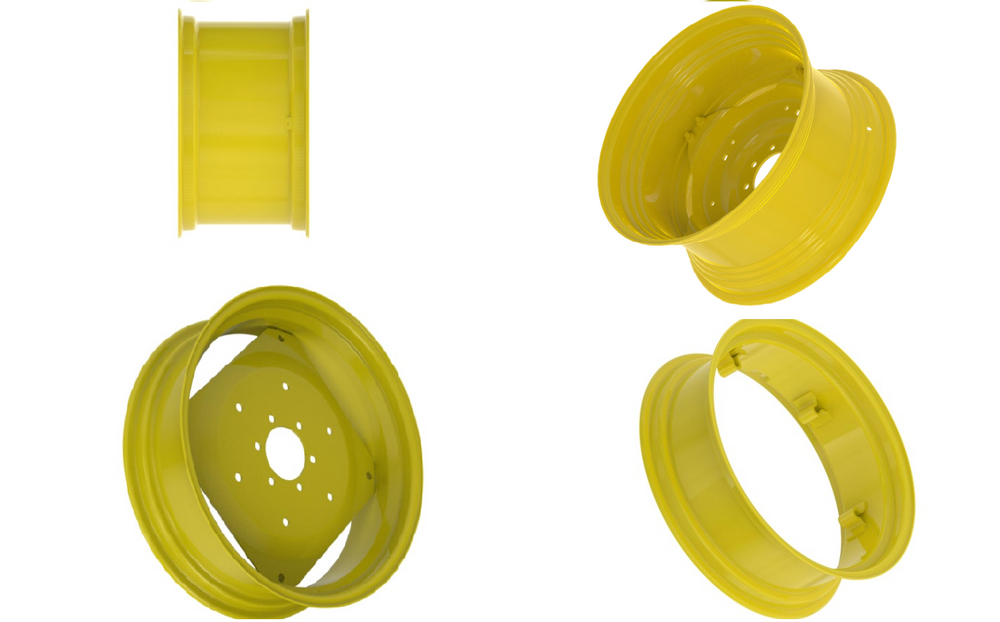

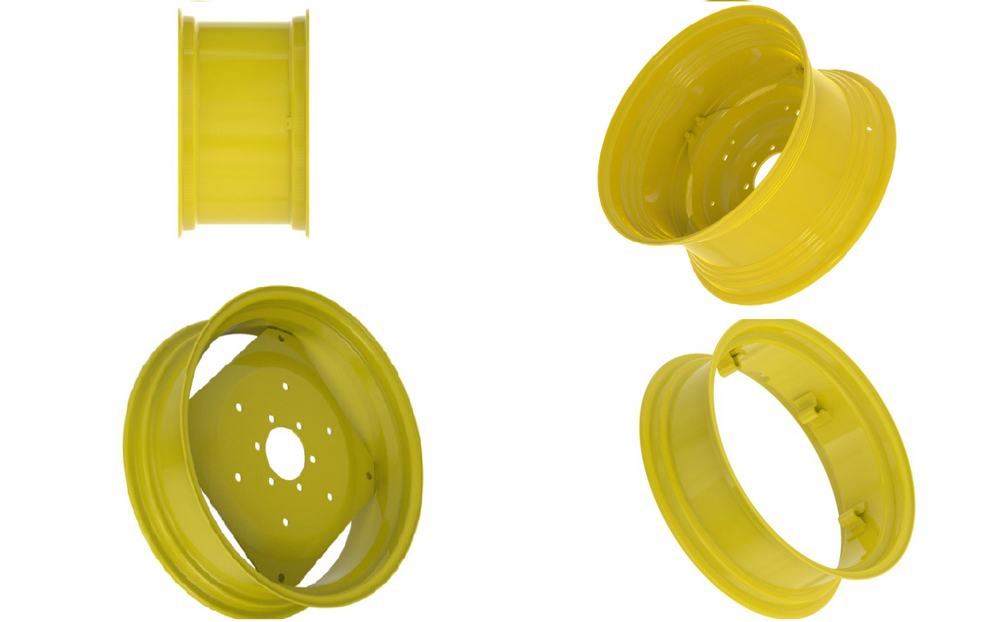

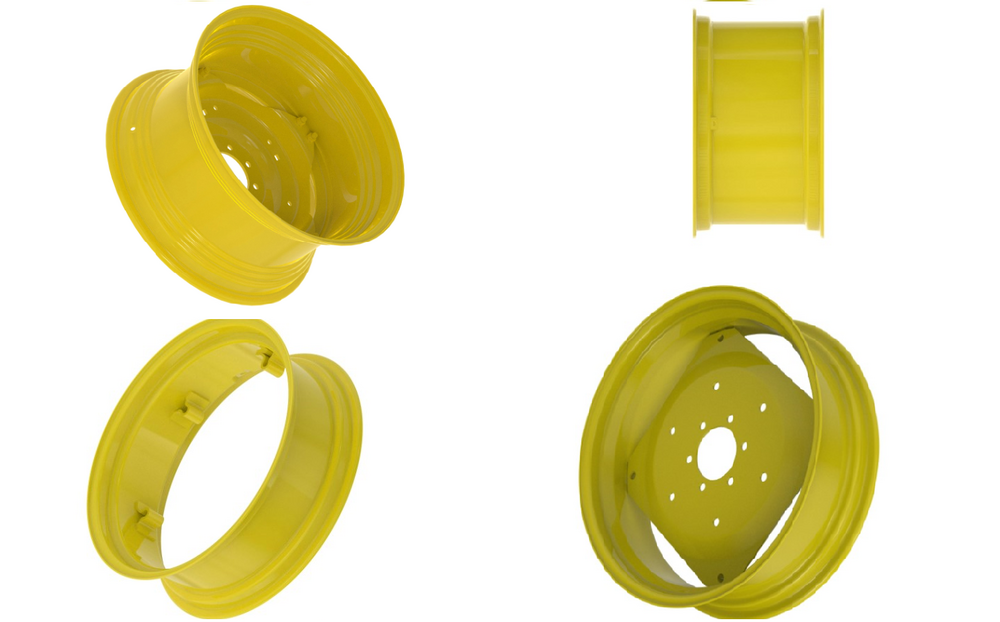

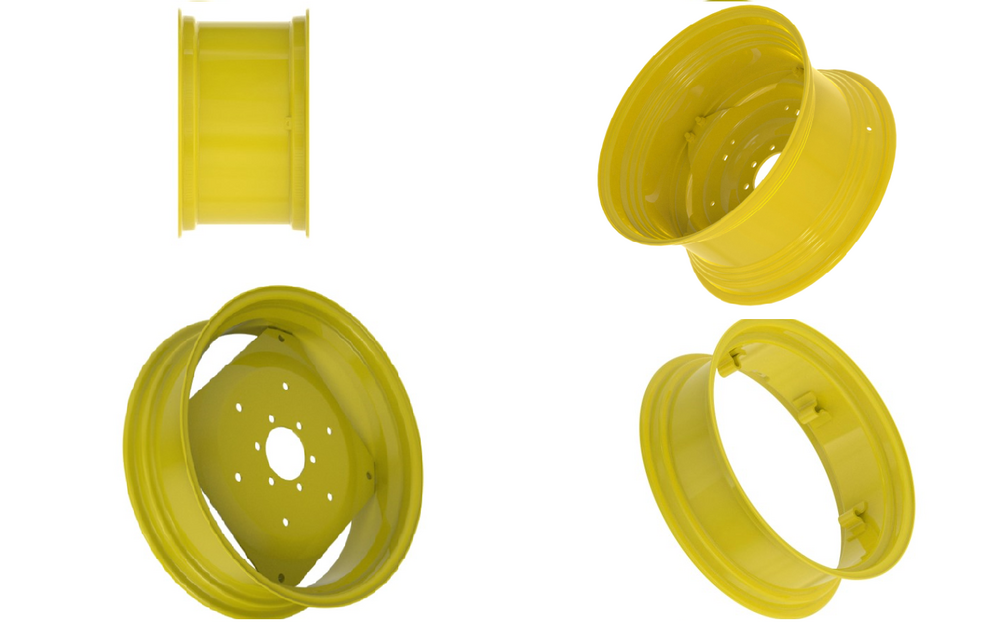

WHEEL AND RIM SPARE PARTS TRACTOR

Product Details:

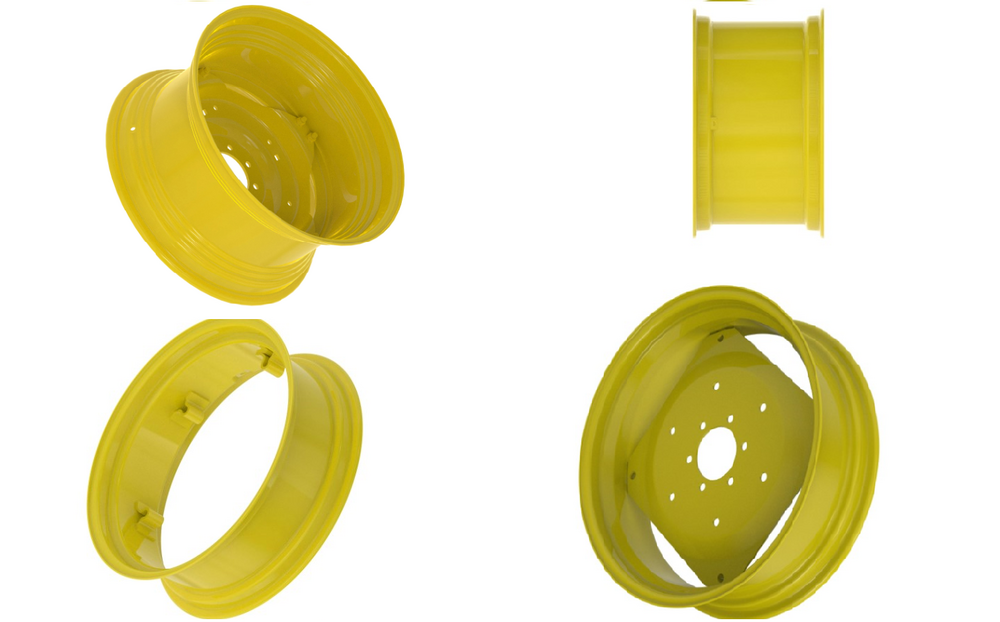

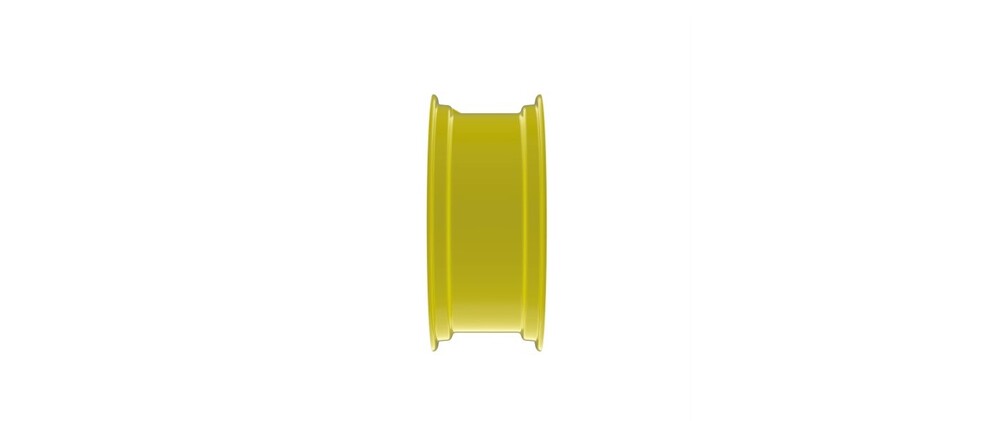

- Part Name Tractor Wheel Rim / Tractor Wheel Disc

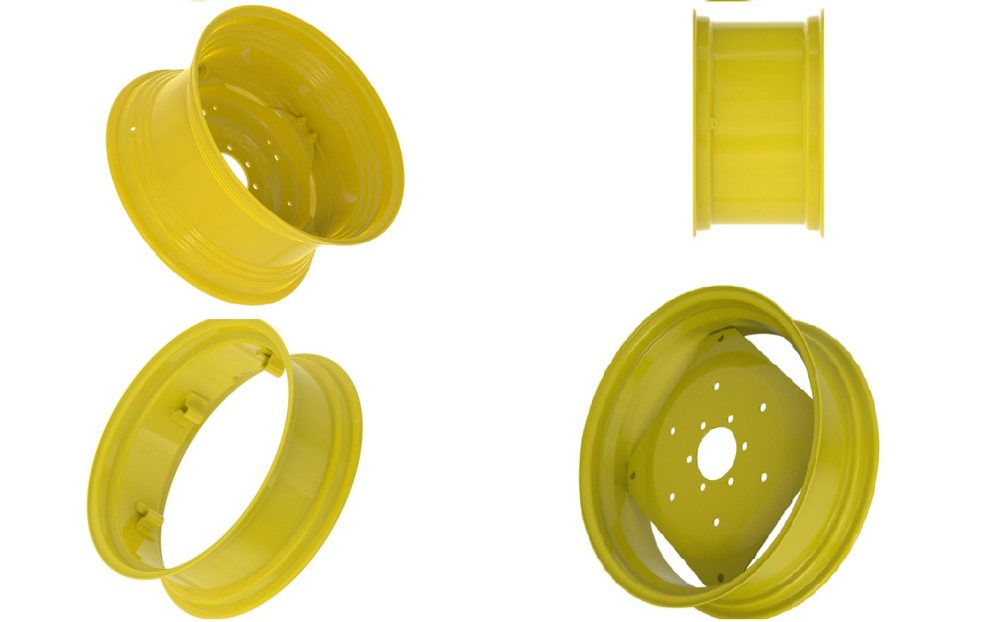

- Load Capacity 3500 Kilograms (kg)

- Lubrication Type Lubrication at bearing mounting, not rim itself

- Hardness High Tensile Strength (value varies with material grade)

- Finishing Smooth Powder Coating / Glossy / Matt

- Bearing Type Designed for Ball/Bush Bearing Fitment

- Pressure Range Designed for heavy load-bearing and shock resistance

- Click to View more

WHEEL AND RIM SPARE PARTS TRACTOR Price And Quantity

- 9000 INR/Unit

- 1.00 - 1.00 INR/Unit

- 1 Unit

WHEEL AND RIM SPARE PARTS TRACTOR Product Specifications

- Tractor Wheel Rim / Tractor Wheel Disc

- Wheel Rim Spare Parts for Tractor

- 3500 Kilograms (kg)

- MechanicalFitted on Axle Hub

- Standard Yellow, Black, Red, or as customer specified

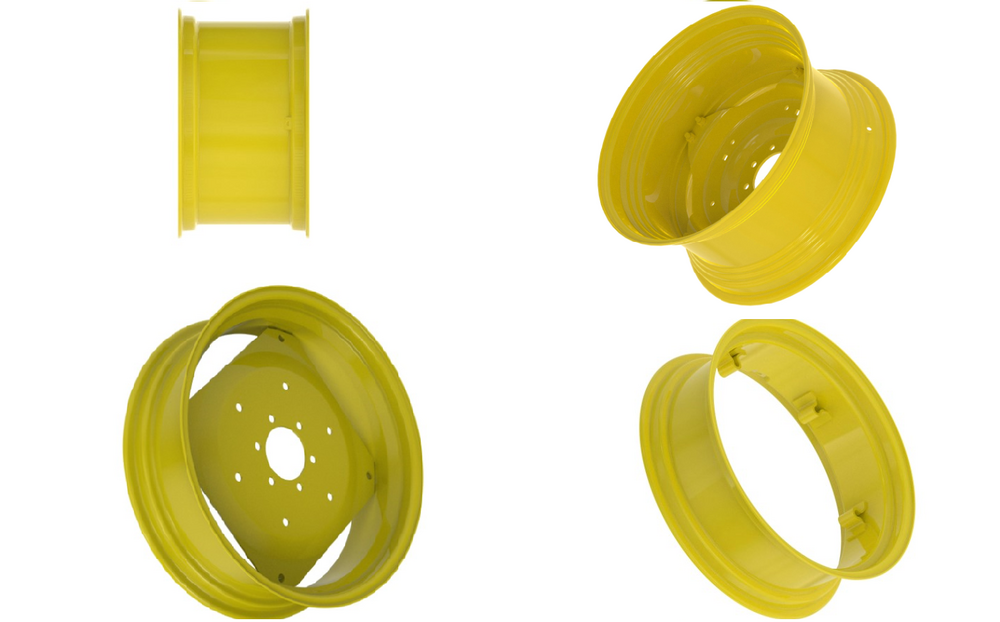

- Advanced Metal Forming, Robotic Welding, CNC Machined

- High-grade Steel/Alloy

- Wheel and Rim

- High Tensile Strength (value varies with material grade)

- Precision Forged and Pressed

- Lubrication at bearing mounting, not rim itself

- Smooth Powder Coating / Glossy / Matt

- Designed for Ball/Bush Bearing Fitment

- Powder Coated / Painted / Anti-Corrosion Treated

- Designed for heavy load-bearing and shock resistance

- 12-25 Kilograms (kg)

- Not applicable for rim (sealing at bearing/hub interface)

- Customizable as per Tractor Model (common sizes: 1624)

- Tractor Front/Rear Wheel Fitting

WHEEL AND RIM SPARE PARTS TRACTOR Trade Information

- 1000 Unit Per Month

- 7 Days

- All India

Product Description

W9 x 20 , W11 x 20 , W13 x 20 , W13 x 20 , W13 x 20

specialized in Tractor Steering Shafts, Steering Worm, Tractor Steering Gear Box Assembly, Tractor Steering Wheels, Tractor Gears, Tractor PTO Hub, Tractor PTO Drive Pinions, Tractor Counter Shaft, etc. for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Field-Proven Durability

Built with high tensile materials and advanced metal-forming technology, these tractor wheel rims excel in harsh field conditions, offering exceptional impact and temperature resistance. Whether confronting mud, gravel, or extreme temperatures, their engineered robustness ensures reliable operation season after season.

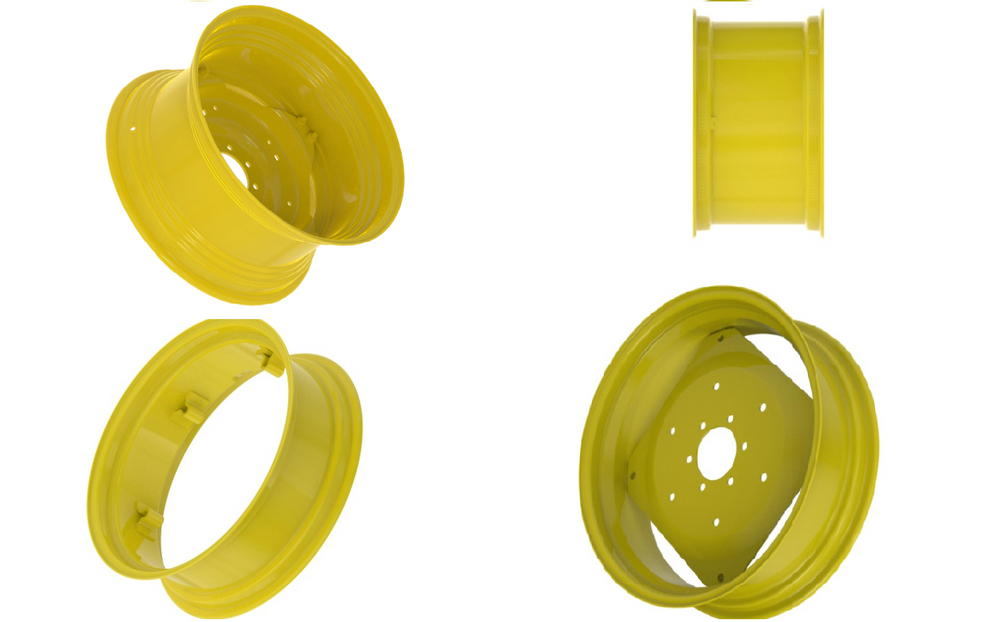

Corrosion and Wear Protection

Each part is finished with premium powder coating or anti-corrosive paint, providing long-term resistance to rust and wear. This meticulous surface treatment extends product life and maintains optimal performance, even under continuous exposure to water, chemicals, and fluctuating temperatures.

Tailored Fit & Application Versatility

Available in standard and custom bolt patterns, colors, and sizes, our rims adapt seamlessly to numerous tractor models and brands. Precise manufacturing tolerances and mounting options ensure a secure, multi-hole fit on various axle hub configurations, suitable for both front and rear wheel applications.

FAQs of WHEEL AND RIM SPARE PARTS TRACTOR:

Q: How are these tractor wheel and rim spare parts compatible with different tractor models and brands?

A: These parts are available in multiple sizes, bolt patterns, and colors, allowing compatibility with a wide range of tractor brands and models. Customization options and adherence to OEM/aftermarket codes ensure precise fitment for both front and rear wheels.Q: What is the benefit of the anti-corrosion treatment used on these rims?

A: Anti-rust coatings and powder painting methods shield the wheel rims from moisture, chemicals, and environmental wear, significantly extending their lifespan and maintaining high performance during prolonged agricultural use.Q: When should a tractor wheel rim be replaced for optimal field performance?

A: Replacement is recommended when visible signs of cracking, deformation, excessive rust, or loss of structural integrity appear, or as per manufacturer maintenance schedules to guarantee safety and efficiency in field work.Q: Where is the product manufactured and what standards does it meet?

A: Our wheel and rim spare parts are produced in India, conforming to international standards such as ISO/TS 16949, ensuring consistent quality, dimensional accuracy, and long-term durability for global customers.Q: How are the rims tested for quality and strength before dispatch?

A: Each rim undergoes rigorous testing for dimensional accuracy and structural strength, including load-bearing and impact resistance trials, ensuring every product matches or exceeds agricultural sector expectations.Q: What is the process for ordering customized tractor rims for specific requirements?

A: Clients can specify required sizes, bolt patterns, colors, and load capacity. Upon receipt, our engineering team designs and manufactures the rims using advanced metal forming and machining techniques, delivering products tailored to your specifications.Q: What advantages does precision forging and CNC machining provide in these wheel rims?

A: Precision forging and CNC machining techniques result in high-strength, perfectly contoured rims with tight tolerances (0.05 mm), enhancing safety, shock resistance, and service life under demanding agricultural workloads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+