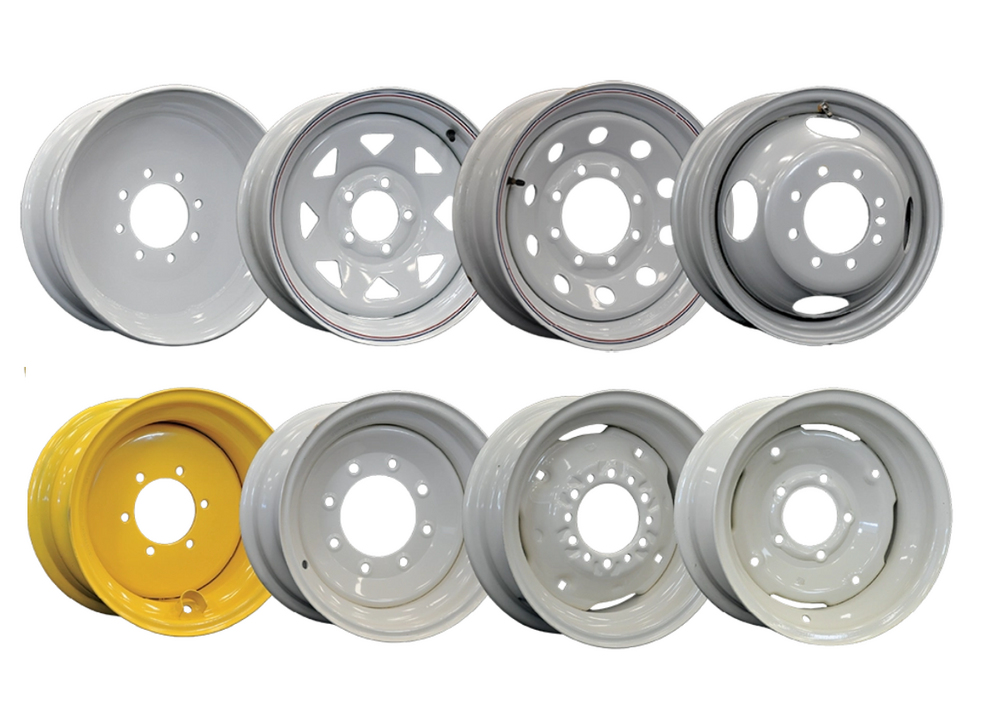

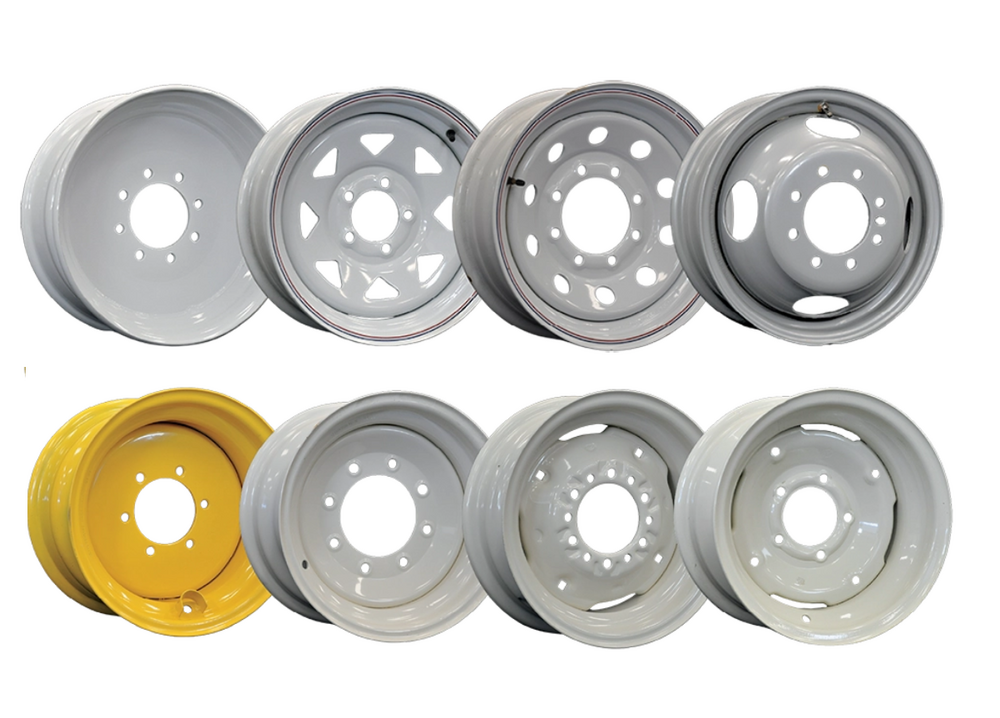

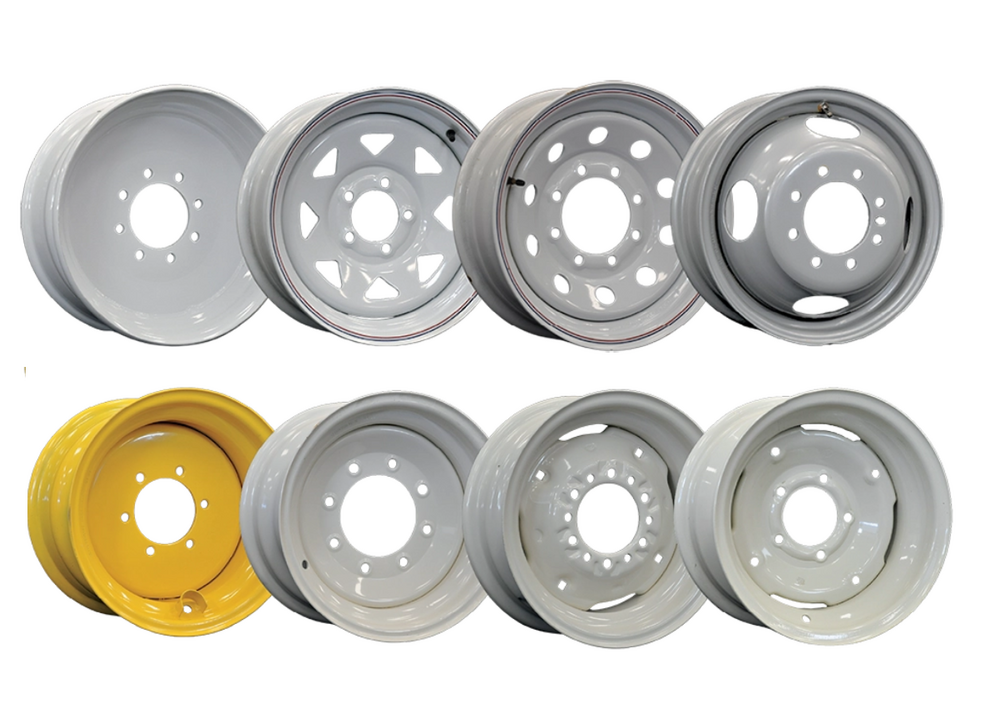

WHEEL AND RIM W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26

Product Details:

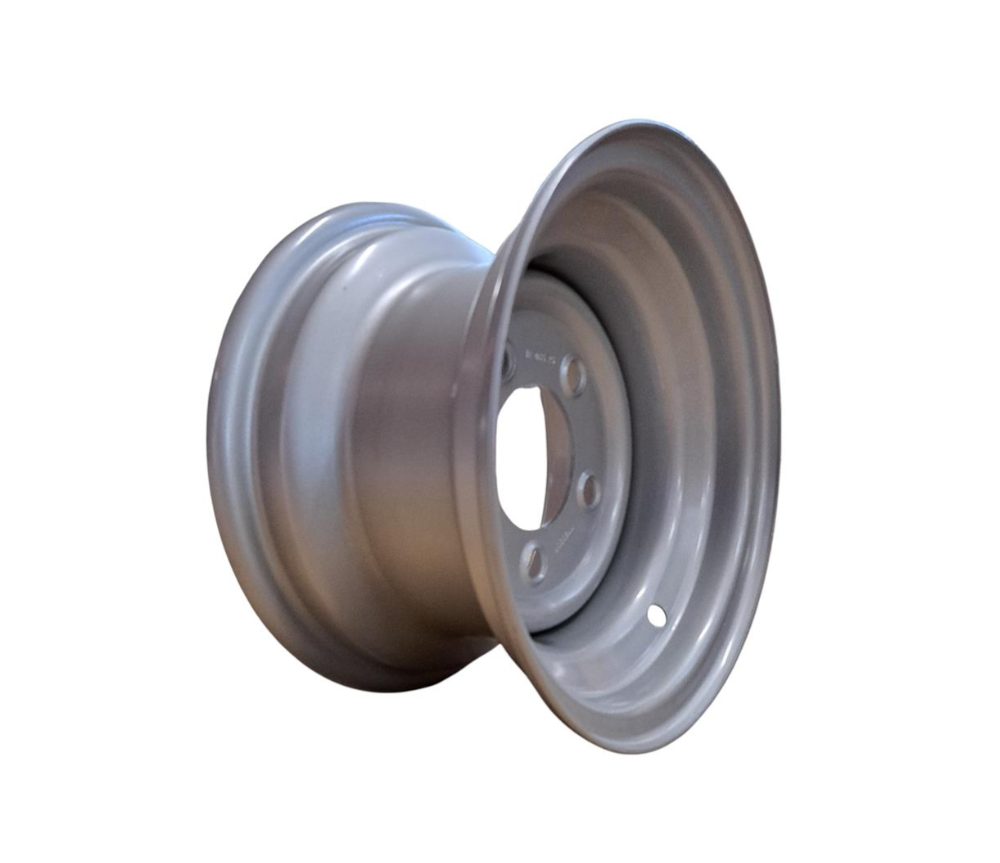

- Part Name Wheel Rim

- Pressure Range Suitable for standard agricultural and industrial tire ratings

- Load Capacity 4000 Kilograms (kg)

- Hardness Medium to High (as per OEM standard)

- Tolerance 1 mm Millimeter (mm)

- Model No W15Lx24, W16Lx24, W18Lx24, DW20Bx26

- Finishing Powder Coated/Enamel finish

- Click to View more

WHEEL AND RIM W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26 Price And Quantity

- 3200 INR/Unit

- 1 Unit

WHEEL AND RIM W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26 Product Specifications

- 4000 Kilograms (kg)

- Suitable for standard agricultural and industrial tire ratings

- Wheel and Rim

- W15L x 24, W16L x 24, W18L x 24, DW20B x 26

- Cold-rolled Steel manufacturing, Precision Welding

- Welded and Pressed Steel Construction

- Wheel Rim

- High-strength Steel

- Agricultural Tractors / Construction Equipments

- Powder Coated/Enamel finish

- Bolt-on / Disc Mounting

- Grey

- 1 mm Millimeter (mm)

- W15Lx24, W16Lx24, W18Lx24, DW20Bx26

- Rim/Wheel Assembly

- Manual/Mechanical

- Varies by model (approx. 40-65 kg each) Kilograms (kg)

- Powder Coated/Painted (Corrosion Resistant)

- Medium to High (as per OEM standard)

WHEEL AND RIM W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26 Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Month

- 7 Days

- All India

Product Description

W14L x 24 W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26 FITS FOR TRACTORW9 x 20 , W11 x 20 , W13 x 20 , W13 x 20 , W13 x 20

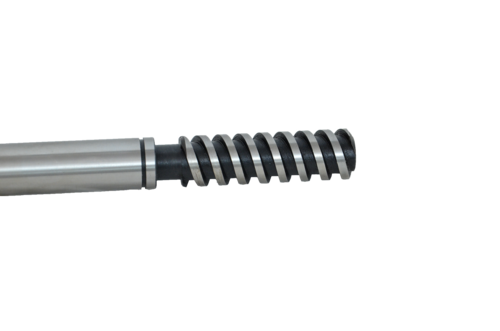

specialized in Tractor Steering Shafts, Steering Worm, Tractor Steering Gear Box Assembly, Tractor Steering Wheels, Tractor Gears, Tractor PTO Hub, Tractor PTO Drive Pinions, Tractor Counter Shaft, etc. for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Advanced Manufacturing & Durability

Utilizing cold-rolled steel and precision welding, these wheels are built to endure heavy-duty field and machine operations. A specialized powder-coated or enamel finish enhances corrosion resistance, ensuring longevityeven in challenging agricultural or construction environments. The application of heat treatment further boosts durability and impact strength, making these rims suitable for rigorous daily use.

Flexible Customization & OEM Compatibility

Rims are tailored to individual requirements, with adjustable center bore diameters and customizable bolt patterns to fit a wide range of OEM equipment. Valve holes are provided according to tire specifications, and color options are available to match customer preferences. This flexibility ensures seamless integration with various tractor and heavy-duty vehicle models, enhancing operational performance.

FAQs of WHEEL AND RIM W15L x 24 W15L x 24 W15L x 24 W15L x 24 W16L x 24 W18L x 24 DW20B x 26:

Q: How are the wheel and rim sizes customized for different vehicles and applications?

A: Each rim is available in multiple dimensionssuch as W15L x 24, W16L x 24, W18L x 24, and DW20B x 26with customizable center bore diameter and bolt pattern. This allows compatibility with various agricultural and construction machinery, ensuring models are tailored to specific OEM requirements.Q: What makes these rims resistant to corrosion and suitable for outdoor environments?

A: The rims feature advanced powder coating or enamel finishes and are manufactured using high-strength steel with cold-rolled technology. This combination provides robust corrosion resistance, vital for prolonged exposure to moisture, chemicals, and harsh field conditions.Q: When is it recommended to use these wheel assemblies for tractors or heavy-duty vehicles?

A: These wheel rims should be used whenever high durability, impact strength, and load-bearing capacity are essential. They are suitable for daily operations in agriculture, construction, and other heavy-duty applications, particularly when OEM compatibility and customized specifications are required.Q: Where can customers order these rims, and what is the minimum quantity?

A: Customers can source these wheel and rim assemblies directly from the exporter, manufacturer, and supplier based in India. The minimum order quantity starts at 10 pieces, allowing for flexible procurement based on operational needs.Q: What is the manufacturing process used to ensure precision and longevity of these rims?

A: The rims are constructed using welded and pressed steel techniques, incorporating cold-rolled steel and precision welding. This is complemented by heat treatment and advanced surface finishing processes to achieve medium to high hardness and extended durability.Q: How do these wheels support different tire types and pressure requirements?

A: Designed for both bias and radial tires, these rims feature valve holes aligned to tire specifications. Their construction supports standard tire pressure ratings, making them suitable for agricultural and industrial use.Q: What benefits do users gain from choosing these OEM-compatible, customizable wheel rims?

A: Users benefit from a product that delivers high impact strength, corrosion resistance, and seamless integration with existing equipment. Customizable options such as bolt pattern, color, and center bore diameter ensure perfect fitment, reliability, and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+