WHEEL AND RIM TRACTOR SPARE PARTS

Product Details:

- Load Capacity Up to 1800 kg Kilograms (kg)

- Finishing Smooth

- Use Agricultural Tractors

- Mounting Type Bolt-On

- Pressure Range Standard Operating Pressure

- Tolerance +/- 0.01 mm Millimeter (mm)

- Model No WR24/WR28

- Click to View more

WHEEL AND RIM TRACTOR SPARE PARTS Price And Quantity

- 1 Unit

- 5690 INR/Unit

- 1.00 - 1.00 INR/Unit

WHEEL AND RIM TRACTOR SPARE PARTS Product Specifications

- Tractor Wheel Rim

- Agricultural Tractors

- High Grade Steel

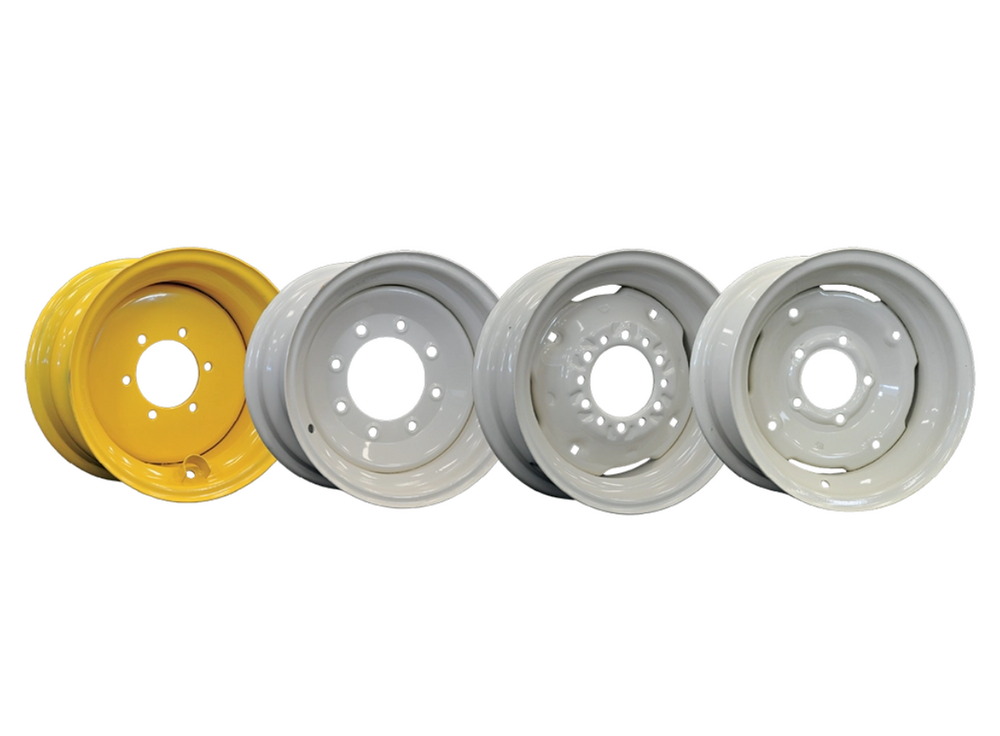

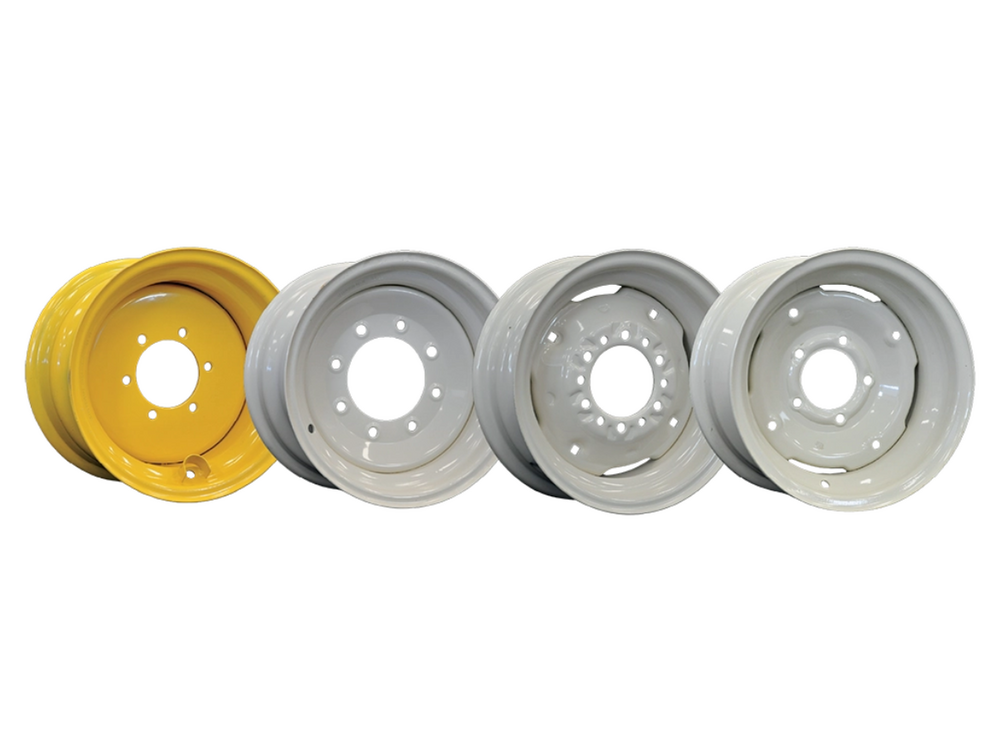

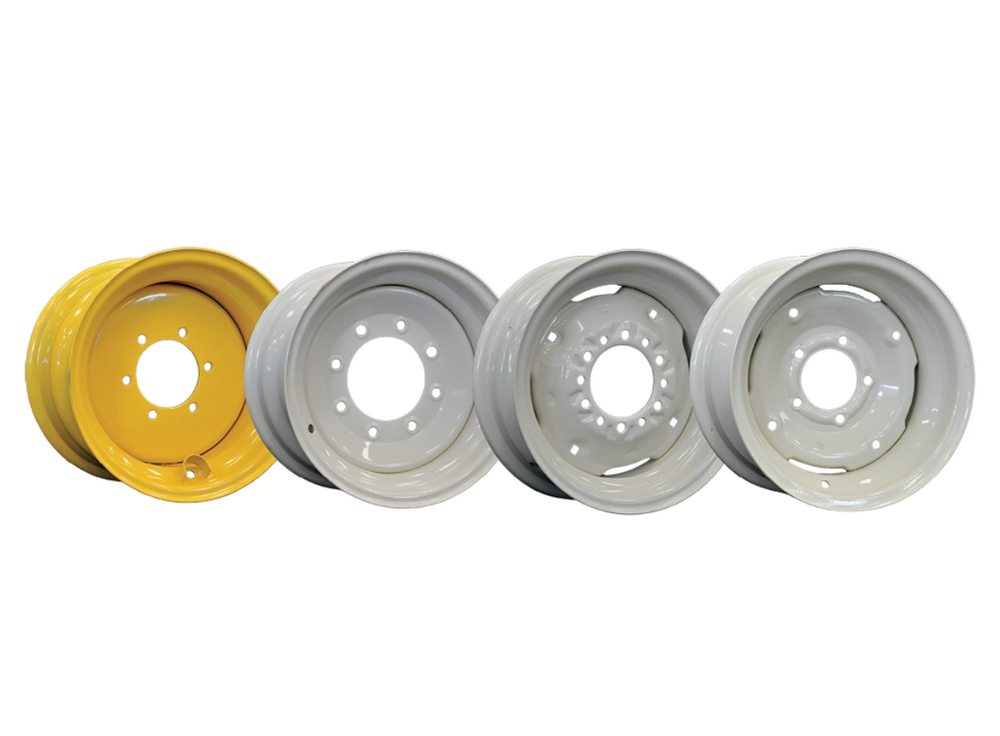

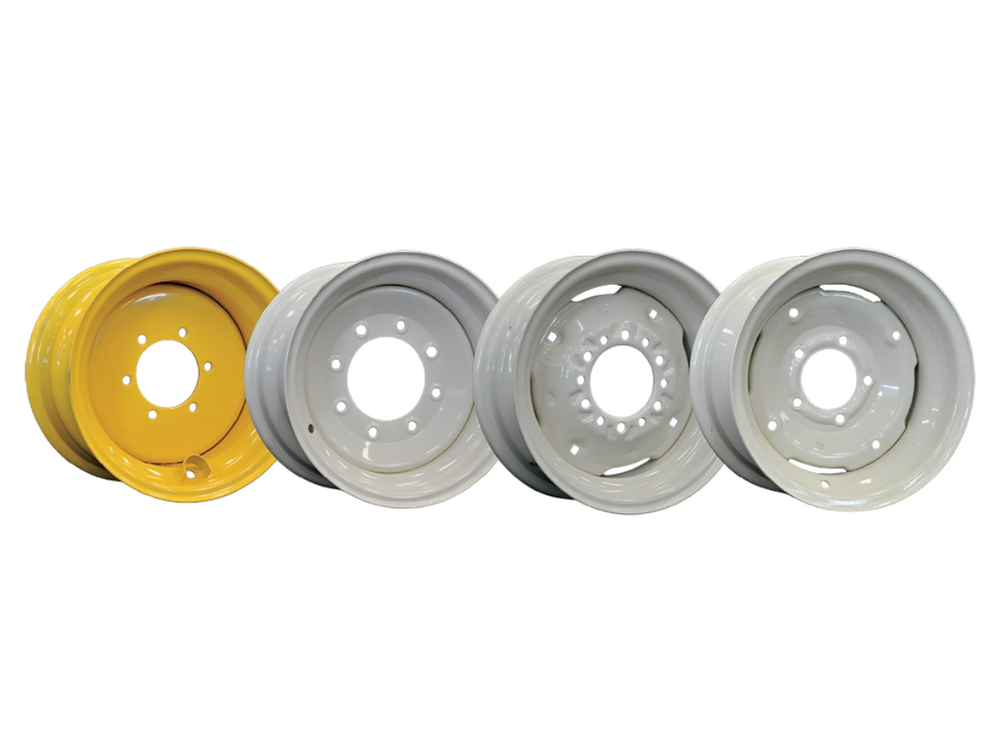

- Silver / Yellow / Black

- Bolt-On

- Manual/Mechanical

- Standard Operating Pressure

- WR24/WR28

- +/- 0.01 mm Millimeter (mm)

- Precision Fabrication

- 38-42 HRC

- Wheel Rim

- 8-25 Kg Kilograms (kg)

- Powder Coated

- Hot Rolled

- Up to 1800 kg Kilograms (kg)

- Standard/Custom

- Smooth

- Spare Part

WHEEL AND RIM TRACTOR SPARE PARTS Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Month

- 7 Days

- All India

Product Description

specialized in Tractor Steering Shafts, Steering Worm, Tractor Steering Gear Box Assembly, Tractor Steering Wheels, Tractor Gears, Tractor PTO Hub, Tractor PTO Drive Pinions, Tractor Counter Shaft, etc. for use in, Agriculture & other Aftermarket Application.

Our Products are marketed across to world over USA,U.K., Europe, Latin America, Australia, Middle East, Far East, African & Asian Continent and our Customers base includes OEMS large rebuilders in Organized Sector and Distribution Houses.

Deals: Massey, Ford, Fordson, Fiat, Kubota, Deutz, Yanmar, New Holland, John Deere, Case IH, IMT, UTB, Ursus, Sawraj, Perkins, Escort, JCB, Mahindra, Steyr.

Business Seller Profile

Zango Super Steering Co.

Plot No. 87,21/3 Rajeev Complex, Mathura Road, Faridabad, Haryana-121004 (INDIA)

Engineered for Strength and Reliability

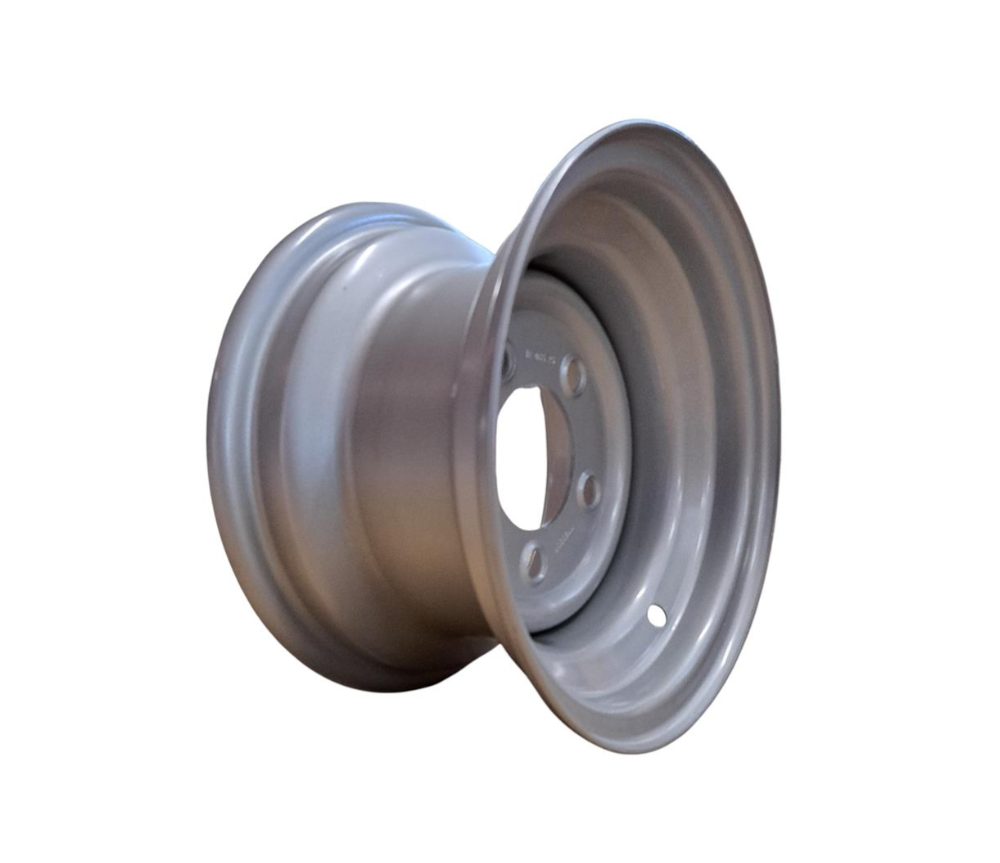

Manufactured from high grade steel and processed through hot rolling, our Wheel and Rim Tractor Spare Parts guarantee impressive strength and an extended working life. With a hardness rating of 38-42 HRC and load capacity up to 1800 kg, these parts withstand demanding field conditions for superior reliability. The powder-coated finishing ensures lasting protection against corrosion, reducing maintenance needs and prolonging service.

Customizable and Compatible Solutions

Whether you require standard sizes or tailored dimensions, our rims are available in both options to suit various tractor models. With customizable features such as bolt pattern, color, and OEM services, each order can be precisely matched to your fleet requirements. This compatibility with major tractor brands ensures seamless integration, while the bolt-on mounting supports straightforward, efficient installation.

Versatile Performance in Challenging Environments

Designed for agricultural versatility, these wheel rims deliver excellent results in field work, tilling, and hauling. Their robust construction supports rotation speeds of up to 400 rpm and functions efficiently across wide temperature ranges, from -20C to +80C. The ribbed or plain surface design further enhances their ability to perform optimally in diverse terrain and weather conditions.

FAQs of WHEEL AND RIM TRACTOR SPARE PARTS:

Q: How do I choose the correct wheel and rim spare part for my tractor?

A: To select the appropriate wheel and rim spare part, review your tractors specificationssuch as bolt pattern (8/10 holes), required load capacity, and size. Our products are compatible with major tractor brands and offer customizable options in size and color to meet your needs.Q: What is the benefit of the corrosion-resistant surface on these rims?

A: The powder-coated, corrosion-resistant surface ensures a longer lifespan for the rims, protecting them from rust and environmental damage, and reducing the need for frequent replacements, especially during intensive agricultural work.Q: When should I consider replacing my tractors wheel rim?

A: Replacement is recommended when you notice visible damage, excessive wear, or reduced performance during fieldwork and hauling. Installing new, high-strength rims improves safety and tractor efficiency in various agricultural applications.Q: Where are these wheel and rim spare parts manufactured and exported from?

A: Our wheel and rim spare parts are precision fabricated in India, where we operate as a manufacturer, exporter, and supplier. We offer reliable delivery and packaging options, including carton boxes and wooden crates, to secure overseas shipments.Q: What is the process for customizing size, color, or bolt pattern?

A: Customization is available for dimensions, bolt patterns, and colors per your requirements. Provide your tractors model details and desired specifications when placing your order, and our OEM services will ensure your parts are tailored accordingly.Q: How are these rims installed, and what mounting type is used?

A: Our wheel rims feature a bolt-on mounting design, allowing for simple and secure installation. This mounting type ensures fast replacement and compatibility across most major tractor brands with standard or custom bolt patterns.Q: Can these rims withstand high rotation speeds and heavy loads during field operations?

A: Yes, these wheel rims are engineered to support rotation speeds up to 400 rpm and have a load capacity of up to 1800 kg, making them ideal for demanding field work, tilling, and hauling tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+